KU1550VP0 Roper Trash Compactor - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

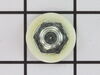

Compactor draw was not opening fully as the wheel bearings had seized

I followed the you tube video instructions provided by customer care. This involved pulling the unit free from the cabinet, removing several screws that held the housing in place, this gave access to the wheel assembly, then I removed the nuts that held the wheel assembly in place. Fitting the new wheel assemblies was easy as was replacing the housing screws. After reinserting the draw and pushing the unit back into the cabinet it worked like new

Parts Used:

-

Andrew from ASHEVILLE, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken handle

Removed 2 screws, pulled out old handle, inserted new drawer handle and replaced the 2 screws.

The drawer handle that was delivered was black and not brown. Black was the preferred color because the old handle was black.

The drawer handle that was delivered was black and not brown. Black was the preferred color because the old handle was black.

Parts Used:

-

Karl from TALLAHASSEE, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trash Compactor ram will not move while motor running, stripped power nuts

Move the unit out of the cabinet, and take off the top cover.The two drive screws are easy to see. unscrew the two screws of one of the power nut covers and remove that cover. With pliers, unscrew the plastic power nut from that screw. Screw on the replacement power nut with the help of pliers and some heavy grease. install the bearing cap. Use the same procedure for replacing the plastic power nut on the other screw. To make sure the piston is level, place the cover on the power screw but do not attach it. Measure from the end of the screw to the top of the cover of the first screw, then adjust the second power nut up or down so the two power screw nut covers are the same distance down from the top of the it's power screw Lift up the piton assembly to close the gap, if any (I used a short piece of rope) , and install the screws on the second power bearing cap. After installation. recheck the distance from the top of the power screws to the power bearing caps is close to the same distance so the piston will be level.. This same procedure could be followed for other brands. Power of the appliance and verify functionality, if OK replace the top cover and push unit back into the cabinet..

Parts Used:

-

Raymond from TACOMA, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rotary switch had finally worn out and was brittle and broken on our 30 plus year old trash compactor.

Removed the switch knob, the outer nut, and the front plate.

Unplugged the old switch from the 3 wires and plugged them into the new switch and put it back together with the new knob. Probably less than 5 minutes.

Unplugged the old switch from the 3 wires and plugged them into the new switch and put it back together with the new knob. Probably less than 5 minutes.

Parts Used:

-

Ray from MUNCIE, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trash Compactor didn't work

The plastic power nut had stripped out on my 12 year old trash compactor. Ordered 2 new ones from Partselect and installed them. Now it works like new again.

Parts Used:

-

john from salinas, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken handle

It is held on with three screws. The PartSelect was the only web site that showed me a picture of the part I wanted. The other web sites said it was no longer made. It was shipped out the day I ordered it, and took a minute to install it. Will order again from your company - great service - thanks.

Parts Used:

-

Thomas from Greene, RI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

none

-

craig from OCALA, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

a plastic bag got caught around the screw and the flange on the nut broke so it couldn,t raise one side so the door was jamed at an angle

I pulled the unit out and tipped it over . I pulled the pan off the bottom then i could put a box end wrench on the screw that was jamed then tuned the screw to loosen the door . i then removed the plastic bag that was wrapped around the screw and put the new nut on and all fixed

Parts Used:

-

Rod from BENNINGTON, VT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench (Adjustable)

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor won't stop

Remove the compactor drawer. Remove the front cover from the controls. TAKE A PHOTO OF THE WIRING TO THE EXISTING SWITCH! Remove the screw from the side of the switch and pull the switch out from the machine. You have to look very carefully at the switch to see the color labels on each prong of the switch. Attach gray wire to top prong (GR), red wire to middle prong (R) and so forth. Compare your work to the photo you took. Replace the switch, front plate and drawer. IT WORKS. YAY. Warning, my husband is dyslexic and attached the wires in reverse order and the compactor did not run at all. So, be sure you match wire to label.

Parts Used:

-

Jane from LUTHER, OK

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

ON RETURNING WOULD NOT STOP RUNNING

REMOVE COMPACTOR DRAWER

REMOVE SCREWS ON FACE PLATE

REMOVE SCREW NUTS ON PART (SOCKET)

SAVE HOLDING PLATE WITH SCREW NUTS

TAKE PICTURE OF WIRE CONECTIONS (IN CASE OF POOR RECALL

USE PLYERS TO PULL CONECTOR OFF OLD SWITCH

REVERS INSTALL

TOTAL 25 MINUTES

REMOVE SCREWS ON FACE PLATE

REMOVE SCREW NUTS ON PART (SOCKET)

SAVE HOLDING PLATE WITH SCREW NUTS

TAKE PICTURE OF WIRE CONECTIONS (IN CASE OF POOR RECALL

USE PLYERS TO PULL CONECTOR OFF OLD SWITCH

REVERS INSTALL

TOTAL 25 MINUTES

Parts Used:

-

Robert from DELAWARE, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rollers wore out

-

Charles from NEWBERRY, MI

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

We had a newly cracked handle on a 36 year old trash compactor.

Took under 5 minutes to unscrew old handle and screw on the new one. Identical part to old handle, compactor looks and works like new!

Parts Used:

-

Deborah from DENNIS, MA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

compactor would not compact the trash

took appliance out of cabinet, found the problem to be two nuts on the big screw bars that drive the compaction machine up and down. These things were wore out. We replaced them and turn the electricity back on and tried the compactor and it worked perfect. Of course here was to top cover that had to be removed and reinstalled . all in all it wasn't to difficult. A new machine cost 1100 dollars. This old one bought in 1988 cost 350 dollars. so thank God this fixed it.

Parts Used:

-

sheila from PINE BLUFF, AR

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

All 4 compactor buttons were missing. The bag kept getting pulled down when we'd run the compactor.

I just used the accompanying screw to attach the buttons to the 4 holes in the drawer. Simple stuff.

I do think I read that the Jenn-Air bags used to come with precut holes, and the bag wold slide over the buttons, holding it in place. I jus get the bag lined up and pulled over the drawer, and cut the holes myself. It works perfectly.

I do think I read that the Jenn-Air bags used to come with precut holes, and the bag wold slide over the buttons, holding it in place. I jus get the bag lined up and pulled over the drawer, and cut the holes myself. It works perfectly.

Parts Used:

-

Paul from Amherst, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One of the roller wheels was worn out

Removed drawer

Pulled out from cabinet

Unplugged power cord

Removed top cover

Removed front panel

Put front on 2x4 block

Unscrewed leveling legs

Used 9/16" socket to remove old rollers

Installed new rollers

installed front panel

installed top panel

Plugged in electric cord

slid back into cabinet

inserted drawer

tested

Works as good as new

Pulled out from cabinet

Unplugged power cord

Removed top cover

Removed front panel

Put front on 2x4 block

Unscrewed leveling legs

Used 9/16" socket to remove old rollers

Installed new rollers

installed front panel

installed top panel

Plugged in electric cord

slid back into cabinet

inserted drawer

tested

Works as good as new

Parts Used:

-

Bruce from ROSWELL, NM

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!