JES8850BAS Jenn-Air Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Built in oven would shut down: fault code F-4

A few years previously I had this same problem and a PROFESSIONAL had replaced the sensor.

Thus this time I knew what the failure was and obtained the sensor from Part Select. Having observed the PROFESSIONAL replace the sensor before; I followed his easy technec only to learn that when the sensor was pulled from the aft wall of the oven that the wires had deteriorated and the plastic plug melted. Therefore it was neccessary to remove the oven from the wall cabinet. Then I removed the panel from the back outside of the oven, cut back the wires and because the kit from Part Select contained additional connectors was able to splice in a replacement connector. Installed the new sensor and reinstalled the oven. LESSON LEARNED; when the PROFESSIONAL had replaced the sensor he had failed to feed the wiring and plug back past the insulated chamber, directly behind the oven, into the cool area assessable by the panel on the aft side of the oven thus the plug and wires were exposed to the heat of the oven. What would commonly be a few minutes job turned into an afternoon project.

Thus this time I knew what the failure was and obtained the sensor from Part Select. Having observed the PROFESSIONAL replace the sensor before; I followed his easy technec only to learn that when the sensor was pulled from the aft wall of the oven that the wires had deteriorated and the plastic plug melted. Therefore it was neccessary to remove the oven from the wall cabinet. Then I removed the panel from the back outside of the oven, cut back the wires and because the kit from Part Select contained additional connectors was able to splice in a replacement connector. Installed the new sensor and reinstalled the oven. LESSON LEARNED; when the PROFESSIONAL had replaced the sensor he had failed to feed the wiring and plug back past the insulated chamber, directly behind the oven, into the cool area assessable by the panel on the aft side of the oven thus the plug and wires were exposed to the heat of the oven. What would commonly be a few minutes job turned into an afternoon project.

Parts Used:

-

Edward from Juliustown, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

21 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

back of knob was cracked and was difficult to turn on

Ordered new knob, it attached easily, with no toolsWorks like new! The part was at my home the NEXT DAY!!!

Parts Used:

-

Susan from Port St. Lucie, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

22 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

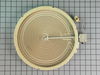

inner element burnt out.

inner element stopped working. took the front panel off and used multimeter to check resistance. it showed open for the inner ring. took the top off, then took the triple element off. visually confirmed broken heating element. replaced element. the repair was straight forward once you figure out where the screws are (8 bottom of front panel, two on each side, then for top 3 each side, 2 on the back -- watch out and don't drop those two). I downloaded service manual from servicematters.com, but it's not helpful, except the wiring diagram.

the quality of Jenn Air range is low. when I bought it, it came with a non-working element. sears replaced the range and now just 1.5 years another one out. once I opened it, there was a loose screw, and two places had missing screws. wire connectors were hard to connect/disconnect.

the quality of Jenn Air range is low. when I bought it, it came with a non-working element. sears replaced the range and now just 1.5 years another one out. once I opened it, there was a loose screw, and two places had missing screws. wire connectors were hard to connect/disconnect.

Parts Used:

-

Ming from Cary, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

18 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

right rear burner was inop for last 4 years

1. tripped circuit breaker for stovetop

2. pulled the stove top out of its cabinet.

3. turned in over carefully due to the glass cooking surface.

4. used 1/4 inch nutdriver on cordless drill to remove all the screws holding the lower cover in place. lifted cover off without removing completely as power wires still attached.

5. did continuity test on burner and found it open circuit while all the other 3 burners had continuity.

6. removed defective burner by removing two more screws and saw element was fried on the cooking side.

7. wrote down all part numbers and put it all back together.

8. changed the burner out when new one arrived by repeating steps 1 thru 6. Pay attention to the correct wiring setup. Do one wire at a time to make sure you don't mess up. MAKE SURE THE CIRCUIT BREAKER IS TRIPPED BEFORE YOU KILL YOUR SELF.

Have a tall one to celebrate the savings of two repair man call out fee's of minimum $60 each time and paying list price for the element. You probably just saved yourself $150.

Tom in Steinhatchee

2. pulled the stove top out of its cabinet.

3. turned in over carefully due to the glass cooking surface.

4. used 1/4 inch nutdriver on cordless drill to remove all the screws holding the lower cover in place. lifted cover off without removing completely as power wires still attached.

5. did continuity test on burner and found it open circuit while all the other 3 burners had continuity.

6. removed defective burner by removing two more screws and saw element was fried on the cooking side.

7. wrote down all part numbers and put it all back together.

8. changed the burner out when new one arrived by repeating steps 1 thru 6. Pay attention to the correct wiring setup. Do one wire at a time to make sure you don't mess up. MAKE SURE THE CIRCUIT BREAKER IS TRIPPED BEFORE YOU KILL YOUR SELF.

Have a tall one to celebrate the savings of two repair man call out fee's of minimum $60 each time and paying list price for the element. You probably just saved yourself $150.

Tom in Steinhatchee

Parts Used:

-

Thomas from Steinhatchee, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

19 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven failed to maintain the set temperature.

Removed the old sensor by removing two screws and pulling the wire out through the hole. Disconnected the connector and discarded the old sensor.

Selected the correct connector of the 3 provided, plugged the new sensor in and threaded the wire back into the hole paying special attention to make sure wire and connector was on the backside of the insulation. Assembled the two screws and tightened.

Selected the correct connector of the 3 provided, plugged the new sensor in and threaded the wire back into the hole paying special attention to make sure wire and connector was on the backside of the insulation. Assembled the two screws and tightened.

Parts Used:

-

Thomas from Clarksville, MD

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Glass top electric range element not working

Turned off the power . Removed two screws in front, lifted top, used a piece of wood to hold up,took off wires to bad element removed old element, replaced with the new one, put wires back on ,closed top,screws to front,on with power and cooked dinner!

Parts Used:

-

Gary from Stockton, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Large 3000 watt burner control inop.

. Ordered part, cut out slide in oven sealant (to stop crumbs from falling between cook top and counter), 2 side screws, four bottom screws, two control mounting screws, unplug, plug in new control ($94), reattach control panel, slide range/cooktop back in, power up and test - total time 1 hr with approx. $200 saved!

Parts Used:

-

David from Clarkston, MI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven door locked and was flashing code F4

First, thanks to PartsSelect for getting the part to me so quickly. I went to the "Instant Repairman" , checked all that applied to my problem. The answer was the sensor, 99% of the time.I used a coat hanger to pull the latch back and open the door. I watched the video and followed the instructions to remove the old sensor. The wires were melted but the plug was still good. I used one of the adapters to install the new sensor, then replaced the two screws inside the oven. I pulled the stove out because I had read in the reviews that you needed to get the plug behind the insulation away from the oven wall. I was lucky ,there was a small hole in the back ,right behind the sensor.I gently pulled the wire and plug to the back ,well away from the oven wall. Put the stove back in place ,threw the breaker and was back cooking again!! My stove has a downdraft vent, took me longer to hook the vent back up than to install the sensor..Oh yes, did I say,I am a75 year old female and I did it all myself..

Parts Used:

-

Mary L. from Trinity, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Glass cracked

removed and replaced cracked cook top. Job went well, but FedEx broke the first two cook tops delived. Suggest the box be marked "Glass - Fragile".

Parts Used:

-

Larry from Scottsdale, AZ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

26 of 49 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

defective oven sensor

Checked online to see what F3 readout on stove meant. It meant replace sensor. Ordered part on a Sunday and part delivered Tuesday, Monday being MLK day. Detached bad sensor(2 screws inside oven)had to pull new sensor connector through hole from behind as insulation was too heavy (only removed 4 screws on right rear panel.Clipped wires together and reattached sensor inside oven. A cakewalk.

Parts Used:

-

sean from easthampton, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

17 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My wife destroyed the oven door seal with oven cleaner...

I ordered the part one afternoon. It arrived before noon the next day. Then I simply removed the old seal (with about 2 dozen spring clips). Inserted the new part by carefully inserting the new seal into its corresponding hole at each end and then worked my way around the seal while inserting each attached spring clip into its corresponding hole.

Parts Used:

-

David from Bexley, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

14 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Code said we needed a sensor

First I removed the two screws that hold the element in place. I then pulled the element out about 3 inches and disconnected the two wires to remove the old sensor. Went on line to find out where to order it from. Ordered it, It was on back order but was only about 1 week to receive. Reversed the procedure. WA LA. It works great.

Parts Used:

-

Janice from Portland, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door glass broken

My wife called a service company and was told that a tech would have to inspect the stove.

service charge 60.00 After inspection the parts would be orderd and a 200 fee for labor plus the parts would be charged at the completeion of the job. 2 weeks for part. I found you on the net orderd the glass. got it in 2 days and I completed the repair in 20 mins. Cost 89.00

service charge 60.00 After inspection the parts would be orderd and a 200 fee for labor plus the parts would be charged at the completeion of the job. 2 weeks for part. I found you on the net orderd the glass. got it in 2 days and I completed the repair in 20 mins. Cost 89.00

Parts Used:

-

Mariano from Staten Island, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

15 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After self cleaning the oven received an error code telling me the sensor was bad.

Removed the two screws holding the element in place. I then pulled the element and wiring out until I saw the connecter. I disconnected the two wires and then chose the correct connector from the package, snapped it back into place, put the screws back, turned on the breaker then tested the oven and found that everything was working correctly.

This is the second time I have ordered from Part Select, the first time was for a front LED panel on the same appliance. With the help finding the part you need and the comments from other customers I have saved a lot of money by repairing these problems myself. Oh, and the best part is the look on my husband's face when he came home and found out the repairs were made by me and not a repairman that he said I should call. He said he would laugh when the first repair by me didn't work but who's laughing now : )

This is the second time I have ordered from Part Select, the first time was for a front LED panel on the same appliance. With the help finding the part you need and the comments from other customers I have saved a lot of money by repairing these problems myself. Oh, and the best part is the look on my husband's face when he came home and found out the repairs were made by me and not a repairman that he said I should call. He said he would laugh when the first repair by me didn't work but who's laughing now : )

Parts Used:

-

Christine from Davie, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

11 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven getting 50 degrees or more, hotter than setting

As the video described I just unscrewed the sensor from inside the oven. Although I couldn't pull the wiring harness through the insulation (the wires were gathered in back with a wire tie) just four screws to loosen the back panel for access to the connection. My wife says it seems to be heating perfectly now.

Parts Used:

-

Joseph from Wappingers Falls, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

10 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!