JDR8895AAS Jenn-Air Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

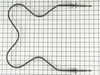

dual oven range, upper bake element melted

Removed oven door and rack. Removed two screws holding element. Disconnected wires to element. One of the wires slipped into the back wall of the oven. The range had to be removed from the counter and back panel removed to gain access to the element wires. Install new bake element in upper oven. Connect wires to element spade lugs. Install rear panel. Restore power at circuit breaker panel. Very important - aways disconnect power before starting work.

Parts Used:

-

JAMES from WAYNE, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the broiler element was not working

turn off all electric to the wall oven. removed the old broiler. replaced the new broiler and turned on the electric. checked the brolier one to see if it worked....it did thanks for the customer service for her help in finding the replacement part.

Parts Used:

-

Gerald from Maiden, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

my oven would not heat to proper temp

I slide the range out and unplugged it from the outlet. I removed the back of the oven ( 8 screws ) using a cordless drill and phillips bit then with a phillips screwdriver I removed the oven sensor (2 screws) then I installed the new sensor , reinstalled the oven back , plugged the range in , slide it back into place and that was it. This repair took about 10 mins and the oven works perfectly. Thanks !

Parts Used:

-

mark from CHAMBERLAIN, SD

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The oven and ranges would not heat up and an F9 error was displaying on the Oven Screen.

So, the F9 error indicates a electrical power issue. First I pulled the oven out and verified I had 240 volts at my outlet.

Then I removed the fire panel over the terminal block and the issue was apparent. The nuts on the terminal block were corroded. This had cause the resistance in the connection to raise and burn up the wire to my oven plug at the terminal block.

I removed the whole back panel and everything else seemed OK visually.

1. I go new connectors for the oven plug, stripped the wires, and crimped on the new connectors.

2. The terminal block DOES NOT come with the nuts to connect the wire to the terminal block. Mine were so corroded they had to be replaced. So I went and purchased the correct ones and installed the terminal block and reconnected all the wires.

3. I applied some dielectric grease to the connections through out the process of reinstalling to prevent it from happening in the future.

Then I removed the fire panel over the terminal block and the issue was apparent. The nuts on the terminal block were corroded. This had cause the resistance in the connection to raise and burn up the wire to my oven plug at the terminal block.

I removed the whole back panel and everything else seemed OK visually.

1. I go new connectors for the oven plug, stripped the wires, and crimped on the new connectors.

2. The terminal block DOES NOT come with the nuts to connect the wire to the terminal block. Mine were so corroded they had to be replaced. So I went and purchased the correct ones and installed the terminal block and reconnected all the wires.

3. I applied some dielectric grease to the connections through out the process of reinstalling to prevent it from happening in the future.

Parts Used:

-

Jared from UNION GROVE, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken levelling leg

-

Linda from Oneida, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Racks were dark and dirty

The first set of racks did not fit. I called the Service rep, gave him the model number and exchanged the racks for the new ones. The new ones fit perfectly and the service was excellent. I would definitely recommend PartSelect.com to anyone who wants to deal with a company with excellent service, parts and representatives who know their stuff.

Parts Used:

-

Geraldine from Germantown, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

6 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Needed to replace the oven door gasket/seal

Removed door from oven by pulling up at the first stop point after opening the door. Removed the outer shell by removing 5 screws. Disassembled the inner door by removing 6 screws. Be careful with the insulation blanket (fits in a molded portion of the inner door). Glass windows can be removed (for cleaning) via a couple screws. Old gasket/seal is held in-place via spring-clips; just squeezed each clip, pushed each thru their respective holes, and pulled off the worn-out gasket. New gasket snapped in-place by pushing the clips thru the respective holes. Reverse the process to reassemble the door. You can do this job in 15-20 minutes. Took us longer because it took some elbow-grease (and patience) to clean the crud off the glass windows.

Parts Used:

-

Daniel from Katy, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven was not correctly heating to set temperature

Removed the approximatly 10 screws that hold on both the upper and lower pieces of sheet metal that cover the back of the oven. Removed the screw holding in the temp sensor. Unplugged and removed the old sensor. Plugged in and installed the new sensor (using one of the included adapter wires supplied with the sensor). Put the 2 pieces of sheet metal back on and plugged in the oven.

Parts Used:

-

Trace from Ofallon, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Igniter switch shorted out and would not stop "clicking"

This is not a hard fix but don't believe the stories that say it'll take 15 minutes. Took me a little over an hour to uninstall the part - maybe 30 minutes to put it together again. Easy to intermediate fix.

First - kill the power using the circuit breaker, pull out the range from the wall & shut off the gas line. Unscrew two screws on the underside of the rangetop (open the oven door to access) then remove a couple more on top by the knobs. After that the top will lift up a bit. Then disconnect the 5 gas line fittings on the manifold & the main gas fitting into the manifold. Remove the back panel to unplug the wire connected to the switch. Now pull out the manifold that has the igniter switch on top. That's about it. When you look at the existing part you can easily see how the new part attaches to the manifold.

Install part & put everything back together.

The cost was around $46 total - hard to beat that!

First - kill the power using the circuit breaker, pull out the range from the wall & shut off the gas line. Unscrew two screws on the underside of the rangetop (open the oven door to access) then remove a couple more on top by the knobs. After that the top will lift up a bit. Then disconnect the 5 gas line fittings on the manifold & the main gas fitting into the manifold. Remove the back panel to unplug the wire connected to the switch. Now pull out the manifold that has the igniter switch on top. That's about it. When you look at the existing part you can easily see how the new part attaches to the manifold.

Install part & put everything back together.

The cost was around $46 total - hard to beat that!

Parts Used:

-

Steve from Everett, WA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Wrench set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door gasket was hard and brittle from baked-on grease - heat leaking around door

Waited for my husband to do it, but when he didn't, I tried it. Very simple! Just pulled the old gasket out of the pinch pin holes in the door, then replaced it. Tuck the one end into the hole at the bottom of the door, then match up the little pinch pins on the gasket with the holes in the door - matches up perfectly! Be sure to tuck in each of pinch pins till they sort of "snap" into each hole. Took me 5 minutes, tops. Works great now, no more lost heat around the edge of the door.

Parts Used:

-

Harlen from Spring Creek, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Two of the burner knobs wore out, had to be replaced

-

Jack E. from Sheridan, WY

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Head burner had something spilled on it which stained it and left a large dark brown spot

Simply remove two screws take old one off and line up and put new one on and replace the two screws. Couldn't have been easier.

Parts Used:

-

Donald from Hudsonville, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

6 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lower Oven element burn out.

Our Maytag electric range has a small oven on top that doubles as a toaster, and food warmer. The lower one is a big oven suitable for Thanksgiving Turkey Etc. It is also a broiler as is the top oven. The top one had the bottom element burn out about 5 months back as well. Now the bottom element on the lower oven had burned out as well. The oven has some age on it, but when I looked to replace it I saw it would be approx $1800.00 - $2000.00 for a new one. I knew the elements were replacable and thought if I should call out the lonely guy, the Maytag repairman. Nope, I pulled the stove out disconnected the 220 power supply. I got the Model number off the back stamped info plate. I looked up Maytags parts on Google and the first one was PartSelect.com. They have easy fill-in spaces for Model and Make and a schematic of the oven and all it's pieces are visually displayed. I found the part I needed and ordered. It arrived in two days, very reasonable, very fast shipping. Pulling out the old elements required only a battery operated screw driver, a flash light, and a magnetic dish to keep track of the screws.The removal of the rear panel takes about 10 sheet metal screws. I marked the leads I disconnected by color with a felt tip pen on the back. I disconnected and removed the aforementioned clips, cleaned inside the oven and placed the new element in, reconnected everything on the back as it had been according to my color assignments, replaced the back with battery operated screwdriver from the magnetic dish, reconnected the 220V power supply. Done, in about 30 minutes; I saved a bunch over a new Stove and at least a couple hundred over a service call. Easy and satisfying.

Parts Used:

-

Joseph from Boerne, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the lower bake element to our stove burned out

Real easy, I removed the two screws holding the element in place, then pulled the element out a few inches to reveal the wire connectors. pulled the connectors from the old element and then replaced with the new one and screwed it back into place and presto! All done and cooking again. The replacement part came in 2 days fast and reliable. Thanks PartSelect.com

Parts Used:

-

Douglas from Wilmington, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lower heat element burned out

Turned OFF the circuit breaker. Unscrewed the old and screwed in the new. Very easy. There were helpful hints from other people on the web site, ie. turn off the circuit breaker first.

Parts Used:

-

Stephen from Glenwood Springs, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!