Parts That Fix Frigidaire Washer Dryer Combo GLET1031CS0 Noisy

Noisy is a commonly reported symptom for the GLET1031CS0 Frigidaire Washer Dryer Combo, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your GLET1031CS0 Frigidaire Washer Dryer Combo that will fix Noisy. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

This rear drum bearing kit is designed for use with dryers. It supports the rear of the drum in your appliance as it tumbles your clothes during the drying cycle. If your drum will not tumble, or if it is making a lot of noise, it could be an issue with this part. This is a ball-and-socket style bearing. You will need to replace this if the bushing has worn out, or if the ball support is damaged. This kit includes one bearing, one ball shaft, one ball bearing, one ball bearing retainer, a small tube of high temperature lubricant and installation screws. Unplug your dryer before you begin this repair.

Replacing your Frigidaire Dryer Rear Drum Bearing Kit

Customer Repair Stories

Dryer drum would squeak and squeal until warmed up, but progressively got worse as the days drug on.

-

Chad from Glyndon, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Wrench set

Loud Squeaking

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum be ... Read more lt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

-

Frank from Boyertown, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

If your dryer does not tumble, will not start, is noisy, or is leaving marks on your clothing, you may need to replace the drum support bearing. The drum is supported at the rear by a bearing, which attaches onto the inside of the rear panel of the cabinet. You will need to remove the dryer drum before completing this repair. Although replacing the drum support bearing is a fairly easy job, you will need tools to complete it. For this repair, you will need a putty knife, a Phillips screw driver, a 5/16 nut driver and maybe a small flat blade screw driver.

Replacing your Frigidaire Dryer Drum Support Bearing

Customer Repair Stories

The dryer tub started screeching and then dropped.

-

Gloria from Murfreesboro, TN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

loud squeeling noise

-

Lewis from Thornton, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers, Screw drivers

This white drum glide is used in a clothes dryer to ensure the front of the dryer drum is supported as it does rotations. *Please note: these are sold individually, however there are two of these in your appliance. We recommend that these be replaced at the same time, this allows for optimal performance and ensures they wear evenly. Each drum glide is approximately 33 inches in length. If the following symptoms occur, consider replacing the drum guide as a solution: dryer is noisy, will not tumble, or leaves marks on clothes. Remember to unplug the power source to the dryer before installing this part. Refer to the diagram provided by the manufacturer for further instructions and guidance.

Replacing your Frigidaire Dryer Drum Glide - White

Customer Repair Stories

drum glides worn out making thumping noise.

Thank you.

-

david from edinboro, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Thumping Noise, Clothes Getting Stuck

-

LT Frank from Wacissa, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

The lower front felt seal with adhesive, also known as a drum felt seal, is used in dyers and allows the drum to easily glide on the front panel. For this repair project, you will need the following tools: #2 Phillips screw driver, #2 square head screw driver, putty knife, and wire bush. If your dryer will not tumble, or makes a squeaking noise when running, replacing this part could solve the problem. Remember to unplug your appliance from the power source for safety before you begin this installation project. Refer to the manual provided by the manufacturer for further installation instructions.

Replacing your Frigidaire Dryer Lower Front Felt Seal with Adhesive

Customer Repair Stories

noise

-

Daniel from San Marcos, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Felt around drum holder worn and torn.

2. Disconnected door switch wires

3. Tore off existing felt

NOTE: The length of the felt that I recieved from PartSelect was incorrect (too short). Since the existing felt was worn and torn at the top, I replaced only a length that matched the length of the new felt.

... Read more >4. Used a razor blade-type gasket remover/scraper to remove the exisitng glue

5. Applied new glue (which comes with the felt) onto the felt and let it set up

NOTE: In hindsite, I would apply the glue to the drum holder instead, as the glue otherwise soaks into the felt. If applied to the drum holder instead, the glue will spread out and provide more surface area for adherence.

6. Installed the new felt, starting at one end and working my way around to the other end, being careful not to stretch it

7. Trimmed the remainder of the existing felt (see first NOTE)

8. Scraped the drum holder below the pulled away ends of the exisitng felt

9. Applied glue to the existing felt, including the trrimmed ends so that the ends do not pull away from the ends of the new felt

10. Re-attached the existing felt

11. Let the glue set-up overnight

12. Reinstalled the face of the dryer, turning the drum so that the felt will not get pushed away

13. Reconnected the door switch wires

14. Turned dryer on, with lid still raised, to check for any drifting of the felt

15. Once assured that the felt would stay in place, put the dryer in service

NOTE: I replaced the felt becasue of the gap that opened due to compression of the felt. The gap, as well as a torn piece of the felt that entered the interior of the drum, was catching clothes and tearing them as they were rotated between the drum and the drum holder. The new felt eliminated this problem.

-

Robert from York, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This drum bearing bracket is for dryers. Drum bearing bracket holds and supports the drum bearing

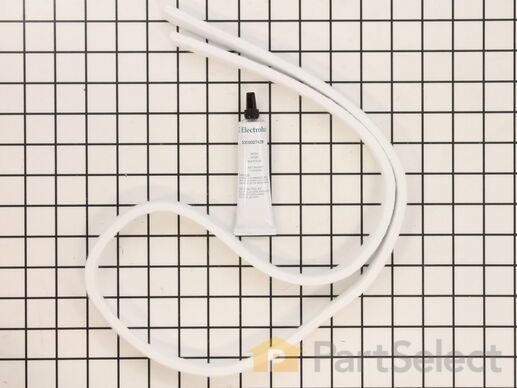

The upper felt seal for your dryer is attached to the top edge of the drum support area, and is held there by a high temperature adhesive. It creates a seal where the dryer door opens and closes, so that heat remains in the dryer while it tumbles. If your old upper felt seal is coming apart, you notice that hot air is leaking out the dryer door, or your clothes are taking too long to dry, you may need to replace the seal. When you order this part, it comes with the upper felt seal, as well as the required high-temperature adhesive.

Replacing your Frigidaire Washer Dryer Combo Front Upper Felt Seal with Adhesive

The multi-rib drum belt is also known as a drive belt and is a part for your dryer. The function of the drum belt is to attach to the motor pulley. It will then spin the drum as the motor rotates. Over time this part will naturally dry out. If your drum belt begins to crack or break, the dryer will not be able to continue to turn. If your dryer is running but your belt will not rotate, that likely means that it has been damaged and needs replacing. The tools you will need for this repair are a putty knife and a screwdriver set.

Customer Repair Stories

Broken Belt

-

mike from perry, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Dryer wouldn't turn, but did make awful sound

Slid the unit forward on plastic bags until back and side were accessible (being careful of the dryer duct and washer water lines).

Removed the vented plate on the back to access the motor and idler arm using a LARGE-HEADED Phillips-head screwdriver.

Pul ... Read more led out the broken belt.

Removed 10 of the 11 screws holding the top on (leave the center front one; undo the front corners last, taking care not to let the front panel slip forward — it supports the drum).

Opened the dryer door and gently pulled the front plate forward, supporting the drum from the inside with one hand so it didn't fall.

Worked the belt around the drum and between the front of the drum and the front panel. Held it mostly taut around the drum to slide it back to the existing belt mark. Grooved rubber side of the belt goes on the inside.

Pushed the front panel back into position while seating the drum on it. Temporarily attached the top with two back and two front screws. (The front panel overlaps the top; the top goes over everything else.)

Scratched my head trying to figure out how the belt goes around the motor shaft and idler arm; searched the web; searched the web some more.

Routed the belt left-to-right over the idler arm pulley, pushed the idler arm to the left, routed the belt around the motor shaft and then up over the drum.

The idler arm should (a) press on the OUTSIDE of the belt, (b) take up all the slack in the belt, and (c) not touch the motor shaft (touching it is what causes the awful noise). The belt should contact the motor shaft past the two nut-like things on the shaft (not between them).

Plugged the unit in and turned the dryer on to test it.

Replaced the other 8 top screws; replaced the vented plate on the back.

Wondered how I ever took having a clothes dryer for granted.

-

Molly from Washington, DC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This blower wheel is a genuine OEM replacement part for your dryer. The wheel can become damaged through use of the dryer, especially if the drive motor shaft, which it is attached to, becomes damaged. This repair will require some disassembly of the dryer. Make sure to disconnect the power source and wear appropriate work gloves while conducting this repair.

This idler pulley assembly is a manufacturer-approved replacement part for your washer/dryer. The assembly includes the idler pulley and arm. The idler pulley provides tension for the belt to rotate the drum. You may notice your idler pulley making a sqeaking or squealing noise, signalling that it needs to be replaced.

Sold individually.

Clamp used for hoses.

This rubber V-style drive belt slips on the motor pulley to bring the basket to the required speed. If you notice a burning rubber smell or grinding noises coming from your washer, your washer does not start, drain, spin properly (will not spin/spins slowly/will not agitate properly), or if your washer shakes or moves during the cycle; check your drive belt for signs of wear and tear. Replace the drive belt if you notice that the belt looks damaged. This OEM part is approximately 35 inches in length, and sold individually.

Replacing your Frigidaire Washer Drive V-Belt

Customer Repair Stories

the belt was all worn out , it make a lot of noise

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

-

CARLOS from BEALETON, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

replace broken drive belt

-

rodney from fairfield bay, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Sold individually.