GI1500PHW7 Whirlpool Ice Maker - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Lack of frequent cleaning resulted in pump failure due to buildup from hard water mineral deposists

This ice maker is really a Kitchenaid appliance.

1. Remove all ice and drain water pan by removing drain cap.

2. Disconnect waterline and unplug ice maker

3. Set icemaker on a work bench unless you like working on your knees, head down.

4. Remove flip out chute and ice scoop bracket.

5. Remove water pan by removing thumb screws

6. Remove single 1/4" head cap screw that holds plastic cover over pump.

7. Remove discharge hose from pump. Pull clear plastic 1/8" diameter water supply line from notch in left edge of pump base.

8. Remove three cap screws holding pump. Two are visible. The third one is behind the pump and requires an 8" extension on the socket.

9. After the three screws are removed the pump drops down. The electric connection must be unplugged. Pinch the tabs on either side to release the plug.

10. Reverse procedure to install new pump. Unless you have really small hands or love being frustrated, don't bother to reinstall the third screw that is behind the pump. The pump stays in place just fine without that screw.

11. After reinstalling the icemaker, clean thoroughly by washing all inside surfaces with a strong bleach solution.

12. Run a cleaning cycle with one quart of strong bleach solution in the water tray. At the conclusion of the cleaning cycle, drain the water tray. Place unit into service. DON'T FORGET TO CLEAN REGULARLY. If the water supply is not chlorinated molds and algae will develop in recirculation hose.

1. Remove all ice and drain water pan by removing drain cap.

2. Disconnect waterline and unplug ice maker

3. Set icemaker on a work bench unless you like working on your knees, head down.

4. Remove flip out chute and ice scoop bracket.

5. Remove water pan by removing thumb screws

6. Remove single 1/4" head cap screw that holds plastic cover over pump.

7. Remove discharge hose from pump. Pull clear plastic 1/8" diameter water supply line from notch in left edge of pump base.

8. Remove three cap screws holding pump. Two are visible. The third one is behind the pump and requires an 8" extension on the socket.

9. After the three screws are removed the pump drops down. The electric connection must be unplugged. Pinch the tabs on either side to release the plug.

10. Reverse procedure to install new pump. Unless you have really small hands or love being frustrated, don't bother to reinstall the third screw that is behind the pump. The pump stays in place just fine without that screw.

11. After reinstalling the icemaker, clean thoroughly by washing all inside surfaces with a strong bleach solution.

12. Run a cleaning cycle with one quart of strong bleach solution in the water tray. At the conclusion of the cleaning cycle, drain the water tray. Place unit into service. DON'T FORGET TO CLEAN REGULARLY. If the water supply is not chlorinated molds and algae will develop in recirculation hose.

Parts Used:

-

Louis from Cheyenne, WY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

77 of 81 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Believed the condensor motor was defective and causing strange odor

First disconnected the quick release electrical connection. Then loosened the three screws that were holding the motor in the bracket. However, space is limited and even with small hands it was rather difficult as the screws were in there very tight. There are a few sharp edges on the bracket and in the surrounding area of the motor area, and nicked myself a couple of times. Removed the fan blade from the old motor and attached it the new motor with the old flat washer/screw. Reconnected the electrical connection and that was that. All-in-all an easy repair.

Parts Used:

-

Nicholas from Frankfort, IN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set

45 of 51 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy and the Fan wasn't blowing like it should

I saved my Whirlpool Refrigerator (Model ET21GKXHN00) and learned a lesson. Don’t put off cleaning the refrigerant coils underneath the refrigerator. I replaced the refrigerator about 10 years ago and began to notice that the sound of this one running had changed slightly. I remembered that’s what happened to the first one just before it died. I removed the panel on the bottom front and saw that the refrigerant coils were covered with dust. It was really bad. I vacuumed them with the “radiator attachment” on the vacuum cleaner and plugged the refrigerator back in. It still didn’t sound right and I couldn’t feel the air blowing out like it should. So I rolled the refrigerator out and removed the back lower cover to see the compressor and the cooling fan. The fan was clogged with dust so I vacuumed that as well. But the fan wouldn’t spin freely by hand. The fan motor only had 3 screws holding it onto the plastic fan bezel and was easily removed by unsnapping the electrical connector on the motor. I removed the fan motor and tried to clean it with a few drops of WD40 on the shaft. But when I put it all back and plugged it in the fan just barely started turning. I unplugged the refrigerator and ordered the fan motor from PartSelect.Com (Item Number PS371043). The picture looked exactly like the motor that was in my refrigerator. I threw everything away in the refrigerator, cleaned it out and left it unplugged until the motor came. The motor arrived in a few days and it looked exactly like the one I had removed. It had the same electrical specifications stamped on the back and the electrical connector was the same and in the same location on the motor. I put the fan blade on the new motor and installed it exactly like the old one was. It only took 15 minutes or so and was very easy to install. When I plugged the refrigerator in the compressor started right away and so did the fan. It ran like a champ. In a few hours the refrigerator got cold and began to cycle on and off like normal and the fan blows like new. The sound is normal and the total running sound is quiet again like a new refrigerator. So for $84.67 I saved my $1300 refrigerator and learned not to neglect checking the build up of dust in the compressor fan section. I’m sure that’s what happens to most of the refrigerators people put out for trash pickup in front of their houses. The cause of the problem is when air flow is restricted across the refrigerant coils too much heat returns to the compressor and eventually causes the compressor to fail. I appreciate that we live in a time when you can order exactly what you need on the internet and make home repairs when you need to. Thanks Part Select for sending me the correct part. It’s nice to have milk and cold drinks again.

Parts Used:

-

William from Centreville, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

35 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

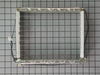

Grid Assembly had a broken wire and would not separate the ice sheets into cubes

I removed the 2 screws on each side of the grid and disconnected the electrical plugs attached to the grid. I slid the broken unit out. I then carefully slid the new unit in making sure not to pinch any of the electrical wires. I replaced the mounting screws, plugged the 3 connectors back into place and turned the ice maker back on. I had ice cubes within a couple of hours

Parts Used:

-

Brad from Bakersfield, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

33 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the top wire on the cutting grid broke and thus no longer cut the ice. It sat on the wire until the ice melted, depositing no ice into the bin

I removed the cutter grid and unplugged the light bulb and wire heating plug ins. I slid the front cover plate off the cutting grid and loosened the screws on the front of the cutter grid and unthreaded the broken, top grid wire, leaving the bottom wire in place as it was in tact.

I then threaded the new wire through the cutting grid frame starting in the center and threading right and then left. While the threading was not difficult, the wire was easily kinked. The process up to this point was only 15 minutes or so.

Once it was completely threaded, I worked for a couple of hours trying to smooth and straighten the wire so that is was somewhat taut and straight enough to create symetrical ice cubes.

My frustration came in pulling on the wire from the center point to each outside ending point where it was to be wrapped around the screw and the screw tightened back down. The wire was fragile enough that it would break, by the time I was finished I barely had enough wire left to touch the screw let alone hook around the screw.

After 3 or four days of successful opperation, the grid quit cutting again. As I took it apart, it was obvious that the weight of the ice was enough to pull the wire, that was already too short, away from the screw. I refastened it again, but think it is unlikely to hold.

If it won't hold, I would be hard pressed to purchase another wire. I may bite the bullet and purchase the entire grid mechanism with the wires already installed. Even though the cost of the entire grid mechanism is $200 more than the purchase of another wire, it may well be worth the ease of installation!

I then threaded the new wire through the cutting grid frame starting in the center and threading right and then left. While the threading was not difficult, the wire was easily kinked. The process up to this point was only 15 minutes or so.

Once it was completely threaded, I worked for a couple of hours trying to smooth and straighten the wire so that is was somewhat taut and straight enough to create symetrical ice cubes.

My frustration came in pulling on the wire from the center point to each outside ending point where it was to be wrapped around the screw and the screw tightened back down. The wire was fragile enough that it would break, by the time I was finished I barely had enough wire left to touch the screw let alone hook around the screw.

After 3 or four days of successful opperation, the grid quit cutting again. As I took it apart, it was obvious that the weight of the ice was enough to pull the wire, that was already too short, away from the screw. I refastened it again, but think it is unlikely to hold.

If it won't hold, I would be hard pressed to purchase another wire. I may bite the bullet and purchase the entire grid mechanism with the wires already installed. Even though the cost of the entire grid mechanism is $200 more than the purchase of another wire, it may well be worth the ease of installation!

Parts Used:

-

Sherri from Ada, OK

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

25 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Ice maker overfilling with ice and would not stop production when full.

Very easy to replace. Down load the Manual online for a completely operating manual. Thermistor can be tested with an Ohm Meter. Proper values are listed in operating manual.

Parts Used:

-

Ray from Terry, MS

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

25 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noticed fridge not cooling as it should

Removed the lower back panel (10 small screws)Found the condenser motor froze up and not moving air across the cooling coils.So I got a small table fan and set it behind the fridge and it kept the fridge cooling for 3 days till the new fan motor arrived. Removed 3 small screws holding the fan motor in the bracket and unpluged the wiring harness.Removed the fan from old motor and used it on the new motor.Replaced the fan in the bracket and plugged the wiring harness back in. Worked great. Very easy.Did not have to empty fridge because table fan kept coils cool. Ordering part was easy and shipping fast.Great job guys!!

Parts Used:

-

Robert from Franklin, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

21 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Not enough water getting into circulation reservoir so ice cubes were very small and the unit was laboring to make ice.

The standalone icemaker: It wasn't making very much ice and made a grinding noise. I watched the water intake hose and saw that the stream water was weak and didn't fill the reservoir like it should before it cycled off. I replaced the water pump (at the front of the unit). Turn water off to the unit. Turn the unit off. Disconnect the 2 hoses-one plastic and one copper. un-screw the pump from the wall of the ice maker. Disconnect the electric connector. Hook the electric connector back to the new pump unit. screw the bottom plastic hose back on. Attach the unit to the wall with the 2 screws. Then attach the copper hose. Turn water back on. Check for leaks. Turn the unit back on. Using a flashlight make sure the reservoir in the back is filled until the water flows into the overflow drain. Make sure that there is a good strong stream of water from the intake hose into the reservoir. You should be good to go. If you have a lot of lime in your water (we do) then you will have to replace this pump every year to 18 months or so. It seems to get clogged up with lime and just doesn't pump enough water to fill up the reservoir in the time allotted for its cycle.

Parts Used:

-

Daniel from Lehigh Acres, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench (Adjustable)

24 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

IceMaker was overflowing so the suspicion was the Ice level sensor was working

The most difficult part of this order was identifying the part. The manual and picture for this model icemaker called the part a Ice level Sensor. No such item could be identified at Parts Select or at Kitchen Aid. After looking at item after item on the parts diagram it was determined the new name was a bin Thermostat not to be confused with the Thermistor, Ice control.

Replacement was quick and easy and took 5-10 minutes. Working fine now.

Replacement was quick and easy and took 5-10 minutes. Working fine now.

Parts Used:

-

Dennis from Houston, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench set

20 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water began to leak under the refrigerator. Source looked like it was coming from control valve suppling water to ice maker and water dispenser.

Followed instructions supplied. It was relatively easy and the parts fit exactly right. Sears wanted twice as much for the part and service would have charged me another $100 to come to my home. I saved over $100 doing the project myself.

Parts Used:

-

jesse from hacienda heights, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

21 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

open drain hole

In pre-replacement of the circulation pump, i had read a story about how to make sure you cover the drain hole to prevent hardware from falling down it. Well I followed the instructions in doing so by covering the hole with a paper towel. After removing the pump i noticed some build up behind it. So like any other person i cleaned it up, and i just happened to use the paper towel covering the hole. Im sure you know what im going to tell you next. When replacing the pump i dropped a screw and yes down the drain it went. After a few laughs between my boss and I, I had to share this. When you block the drain with something leave it THERE until the job is done.

Parts Used:

-

James from Redding, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Ice Maker quit making cubes, cutter wire broken

First I removed the cutter grid assembly by removing two screws. Also disconnect the wire that powers the grid. Once on the bench, simply remove the broken cutter wire. String in the new wire, starting at one end and working back and forth to the other end. Tighten the terminal screw on the first end, and then "strum" the wires, one at a times, pulling the wires taught. Pull the excess wire thru the second terminal, until all wires are taught, with equal tension. Tighten the second terminal screw, and cut off excess wire at both ends. Re-assemble cutter grid into Ice Maker.

Problem solved!

Problem solved!

Parts Used:

-

Kenneth from New Richmond, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The water was not circulating over the cold plate

I removed the cutter cover in the front of the ice maker (3 screws), than removed the circulating pump cover (1 screw). Remove the drain tube from the cover before removing the cover from the icemanker. The drain tube is removed by pulling straight down and twisting. Remove the circulating pump, utilizing the 4 inch extension (3 screws). Reinstalled all in reverse.

Note: install a plug in the drain hole in the bottom of the ice maker (paper towel etc). I dropped a screw on the installation and it fell in the drain hole. It did not impede the drain flow. It has now found a new home.

Note: install a plug in the drain hole in the bottom of the ice maker (paper towel etc). I dropped a screw on the installation and it fell in the drain hole. It did not impede the drain flow. It has now found a new home.

Parts Used:

-

Benjamin from Chesapeake, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

16 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

ice maker made ice but pump ran too much

First I removed the front door by removing the screw on the top hinge. Then removed the upper hinge plate. This allowed removal of the top corner retaining screw. Removed screws at three other top corners. Now I could raise the top at a 45 degree angle to remove the controller cover. The controller was connected with several wire clips and held in place with two screws. Quick swap out and reverse order completion. Ice maker works like new!

Parts Used:

-

David from Collierville, TN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

19 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Circulation pump failed. Replaced same.

Unplugged ice maker from power source. Removed water reservoir using wing nut driver. Removed pump cover using nut driver. Removed water hose from pump discharge. Removed wiring harness from pump. Removed small water fill hose from pump bracket. Removed 3 screws holding pump assembly using nut driver. Replaced pump in reverse order. Plugged in ice maker and watched it begin to fill with ice within the hour. A very straightforward repair. Saved myself about $500 compared to the estimate that Sears gave me.

Parts Used:

-

John from Covington, LA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

12 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!