EHS342-OF (EHS3420OF) Caloric Cooktop - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

One burner didn't work all the time the other would go red hot

I unplugged the stove from the outlet, then removed the two burners I was going to be working on and the drip pans. Then I raised the top part of the stove and removed the screws holding the plug-in blocks to the stove. Then I cut the two wires going to the old plug-in block and stripped the wires back to match the new wire parts. Then I placed the sleeves over the new wires, then I placed the new wire beside the wire I stripped on the stove and screw on the wire cap making sure it was tight. I repeated this three more times, once I had all four wires connected I then placed the sleeves over the connections and heated them up until they were formed around the connection. Once I had all the connections done I placed one wire at a time into the plug-in block until it locked into place ( I looked at my old plug-in blocks first to make sure I placed the new wires in the correct way ).I then used the metal mounting bracket that matched my old ones and snapped the correct one onto each plug-in block. Before mounting them onto the stove I compared them to my old ones to make sure they were correct. Then I used the new screws to mount them to the stove. I took a second look at everything I had done before closing the top cover of my stove. After lowering the cover back into place I put both the drip covers in place and then installed the burners.I then plugged the stove back into the outlet and tried the burners. This was very simple and the video on the web site shows this very well which made my job very simple.

Parts Used:

-

Phillip from Pekin, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Purchased home but stove had no broiler pan.

-

Raymond from BLOOMINGTON, MN

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

14 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

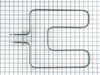

Broiler burned out

The Job didn’t take very long at all. I pulled the unit out and unplug it before I started the repair. I had to remove the back two access cover plates to get to the two wire leads that connect the broiler. I don’t believe there was enough wire to be able to do it all from the front side. Next I disconnected the two wires that connected it while remembering what color goes to the correct side (just incase this does matter). After removing the wires I moved on to remove the element with a Philips screwdriver. The new part already had the hangers on it so I reused the old screws and installed the new element. Next I reconnected the wires in the back and re-installed the back panels. I plugged it up and it works as good as new now. This was definitely a lot cheaper to fix this myself than hire a repairman.

Parts Used:

-

David from Lewisburg, TN

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

8 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rivet broke on the right side oven door hinge

Regarding my right side oven door hinge replacement, P/N PS2172201

After reading that other people had trouble threading the screws into the new hinge, I looked at the drilled mounting holes in the new hinge. Neither hole was threaded. The smaller hole used a self tapping sheet metal screw which works fine. The larger hole gets a machine screw and will not self tap. Since the instructions say put the screw in "once" to tap the holes before installing the hinge, I tried this. It doesn't work, regardless of what the instructions say. The larger hole should come from the manufacture threaded. I do have a tap and die set so I tapped the hole myself. After that, the installation is a 5 min. ordeal.

Take the two screws, one on each side, out that hold the oven door on the hinges. The door will then pull straight off the hinges. Take the storage drawer below the oven out. Unscrew the top and bottom hinge screws and pull the old hinge out from inside at the bottom. Put the new "threaded" hinge into position and hold from the bottom, inside. Screw in the two screws, large one on the top end, and put the door back on. You can open both hinges about 30 degrees to allow the door to slide back on the hinges easily. Put the last two screws in that hold the door to the hinges and you are done.

Really very easy and saved several hundred dollars in repair bills. I might add that my hinge arrived on time 3 or 4 days after the order was placed.

After reading that other people had trouble threading the screws into the new hinge, I looked at the drilled mounting holes in the new hinge. Neither hole was threaded. The smaller hole used a self tapping sheet metal screw which works fine. The larger hole gets a machine screw and will not self tap. Since the instructions say put the screw in "once" to tap the holes before installing the hinge, I tried this. It doesn't work, regardless of what the instructions say. The larger hole should come from the manufacture threaded. I do have a tap and die set so I tapped the hole myself. After that, the installation is a 5 min. ordeal.

Take the two screws, one on each side, out that hold the oven door on the hinges. The door will then pull straight off the hinges. Take the storage drawer below the oven out. Unscrew the top and bottom hinge screws and pull the old hinge out from inside at the bottom. Put the new "threaded" hinge into position and hold from the bottom, inside. Screw in the two screws, large one on the top end, and put the door back on. You can open both hinges about 30 degrees to allow the door to slide back on the hinges easily. Put the last two screws in that hold the door to the hinges and you are done.

Really very easy and saved several hundred dollars in repair bills. I might add that my hinge arrived on time 3 or 4 days after the order was placed.

Parts Used:

-

Roger from Pleasanton, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Electric burner on stove would not work

The first thing I did was to turn the power off to the stove by turning the Stove circuit breaker off at the Main breaker panel. I next removed the 4 burners by pulling them out of their plug-in blocks. I then removed the four screws that held the top of the stove to the body so I could access the bad plug-in block, the screws were located under each of the burners drip pans. I next removed the screw holding the bad block. I lifted up the top of the stove so as to relocate the bad block, with wires connected, through the opening of the back burner. The bad block was located in the front rt part of the stove and by rerouting this to the back I could lay the top down and have easy access to what I needed to replace. I next used the knife to make a cut down the length of the old shrink tubing so as to gain access to the old splice. I next removed the old wire nuts which allowed the removal of the bad block. I then install the new clips into the new block. I installed one each shrink tubing onto each of the pigtails from the new clips and twisted the one new wire to the stove wiring harnes were the old wire was connected . I connected the seconded wire in the same manner. I pulled on each wire to verify that they were tightly secured together. I then positioned each shrink tubing over each wire nut (you have to fold the wire nut and wires down against the wire so as the shrink tubing will slip over the wire nut) and used a heating tool (hair dryer on high) to shrink the tubing around the wire nutted connection. I next installed the metal clip that would hold the block to the stove top. I placed the new block back to the location where the old block came from and secured it with the new screw provided by the kit. I re-installed the four screws to hold the top down, plugged in the four burners, turned the power on at the breaker box and turned the burner on to test that it work.

Parts Used:

-

Ronald from Fresno, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Electric burners where consistently intermittently working right. Sometimes they would work on High but not able to adjust to low heat. Sometimes they would just not want to come on at all. Occasionally there was a spark at the connection. If I jiggled the element just right it may or may not wo

Thought we was going to have to replace the range all together, due to most parts not being available for this model anymore. Since this is an expensive model, we did not look forward to having to replace it. So I thought just by chance I would check to see if anyone had parts to help in repairing it. Part Select did happen to have the Surface Plug-in block kit that was needed. After going at least a year with this problem, I am sooooo happy to say it is finally fixed and working great! Thanks much Parts Select.

Parts Used:

-

JOAN from Pickford, MI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Electric stove burners working intermitantly.

replaced old, worn blocks with new style surface plug in block kits - all 4 burners. Completely resolved the problem at very low cost (less than $50.00).

Parts Used:

-

Michael from St. Louis, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven door would fall off when you opened it

left side hinge was broken. I removed 2 screws to release the old hinge and replaced it with the new hinge.

Part select.com made it easy to pick out the part from the diagram supplied on the web site. After it was ordered it arrived 2 days later.

Part select.com made it easy to pick out the part from the diagram supplied on the web site. After it was ordered it arrived 2 days later.

Parts Used:

-

Arthur from Ridgewood, NJ

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old hinge snapped a rivet. It could no longer hold the weight of the door.

I removed the two screws and pryed out the old hinge. I then put in the new hinge. The new one fit well. I went to screw it in with the supplied screws. The screws not only did not fit the hole tapped in the hinge (too big, different tread) but both screws were different from each other. They were different sizes and different types all together. I tried re-using the screws from the originol hinge but they also did not fit. I then got my own self tapping machine screws and finished the job. This job should not have been that hard. If they had supplied the correct screws, It would have taken all of five minutes.

Parts Used:

-

Frank from Farmingdale, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Sparks emitted at burner connection and burner does not work.

1. Turn off circuit breaker, pull out element and remove reflector pan.

2. Unfasten terminal block mounting screw and remove terminal block from casing.

3. Cut wires as close to defective terminal block as possible (not as per instructions) since you will need the maximum possible length of wire.

4. Slip on heat shrink sleeves, strip stove wires and connect to new terminal block per instructions.

5. Heat shrink sleeves per instructions.

2. Unfasten terminal block mounting screw and remove terminal block from casing.

3. Cut wires as close to defective terminal block as possible (not as per instructions) since you will need the maximum possible length of wire.

4. Slip on heat shrink sleeves, strip stove wires and connect to new terminal block per instructions.

5. Heat shrink sleeves per instructions.

Parts Used:

-

Doug from Puyallup, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One hinge was broken and the other was Sprung

Removed the door and old hinges and reinstalled the new hinges and added some screws to better support the door ( it was bending a little at the middle and the door would not shut all the way. Now it works fine.

Parts Used:

-

William from Social Circle, GA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

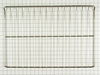

Son accidentally melted alot of plastic in oven.

I took out ruined racks. Cleaned the oven, getting rid of all the melted plastic. Once oven was sparkling clean, I slid in the new racks I bought from here. (The easiest part).

* * * *

I'm very thankful to have found this site. My oven has been "out of order" for over 3 years. It's so nice to be able to use it again! =)

* * * *

I'm very thankful to have found this site. My oven has been "out of order" for over 3 years. It's so nice to be able to use it again! =)

Parts Used:

-

Virginia from Holts Summit, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broil element broke

Top (broil) element broke in two on oven. Ordered part,it was there in three days. Quick fix, removed screw holding element to oven wall, unplugged wires, then just swaped out elements. Re-attached wires just as they were on old element and screwed back into same place and oven is working again.

Parts Used:

-

Randall from Cartersville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Right hinge broken: left hinge bent

Instructions with parts are minimal. Looked at exploded drawing and read other installation descriptions on site. From the read I knew it was easier than it looked. Opened oven door. Unscrewed screws about 1/3 of the way up on both sides on inside face of door; these are the only thing attaching the hinges to the door. (Save all the screws you remove - they make work better than the ones with the parts.) The door can now be pulled off the range. I pulled the broken part out of the right side with pliers. Remove the screws below and about 8" up from the hinge on each side. When this is done you can pull the hinge out from the slot from the front. Open the new hinges up and they will slip through these same openings and position them as the ones you removed were positioned. Replace the screws. On the parts I received the lower screw holes on the hinge were not tapped. The original screws worked a bit like self-tapping ones. If you lose any parts or need to get to the hinge from the back you can take out the drawer.

Parts Used:

-

Stephen from New York, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stove-top Burner intermittently shut off and on-wouldn't heat properly

removed old Plug-in block by removing 1 screw and cutting 2 wires. (Screw was so tight and rusty that I had to use vise grips to remove it). Installed new Plug-in block with wire nuts and heat shrink wraps. YOU just have to make sure the wires are seated in the block properly. This job was much easier than I anticipated. The burner works great now!

Parts Used:

-

George from New Bloomfield, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!