DLG330RAW Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

dryer roller wheels

-

Kenneth E from Almont, MI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

Duct fan separated

First time through it was an interesting adventure... Had to take the front completely apart... When I took the drum out that is when a roller earning had melted off... And the limit timer was broken... The second time through it went faster... And I had my son help... He is not mechanically inclined but he did well...

Parts Used:

-

Kelley from Eureka, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Correct noise problem

Remove drum assembly, replace drum roller, belt with Pulley wheel bearing. The whole problem was corrected and the unit now runs like new.

Parts Used:

-

Angelo Barreto from Flowery Branch, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Door Latch broken

-

Eugene from Arlington, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Very noisy, stopped during cycle, would restart after a while but was getting worse.

I removed the front panels, lint screen, ductwork to fan, motor assembly, drum, drum rollers, and vent pipe to outside. I then cleaned years of accumulated lint and dust from the cabinet. Replaced the drum rollers, drum glide, idle pulley and motor assembly. The hardest part was getting my arm in to place the idle pulley onto the drive belt.

Parts Used:

-

Michael from Hill City, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

Replaced belt, fronrt felt, glides

Not quite as show on your repair intructions. But, all in all not that difficult. Things went very well. However, in the midst of the repair I found I had to replace other worn out parts.

Parts Used:

-

Angel from Georgetown, DE

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

would not tumble

I first unplugged the dreyer from the wall, I then used the putty knife to push clips in on top of the dreyer and opened the top. I used a nut driver to remove the front panel and unplugged the light and door switch wires. I then reached under the drum and removed the belt, and then lifted the drum out of the cabinet. I used snap ring pliers to remove the rollers and replaced.them with the new ones. After installing the new rollers I placed the new belt around the the.drum and lifted the drum by the belt placing it back into the cabinet. With the drum back in place I reattached the front panel and turned the drum to make sure it was not hanging up on the felt rings. With the drum moving freely and the belt hanging down I layed back in front of the dreyer and put the belt on the motor and reached up to.the tension pulley and placed the belt under the pulley. Once the belt had tension on it I again manually rotated the drum to make sure it wasn't binding anywhere. All was good so I replugged the light and door wires, shut the lid and plugged the dreyer back into the wall socket, turned it on and it worked great. From start to finish it took about.40 minutes and half that time was spent cleaning out the cabinet which had quite a bit of lint. I have used the.dreyer several times since the repair, and this completely took care of the problem. I highly recommend ordering the rollers along with the belt as mine were well worn and it saved me from having to take it apart twice. All in all a very eazy do it yourself project.

Parts Used:

-

DAVID from HIGHLANDS RANCH, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

Replaced pressure door switch

-

Robert from Dacula, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Idler pulley seized up, causing half of it to disintegrate and throw the belt

I would have been sick to have spent 100 bucks or more on a repair guy, or worse, several hundred on a new one. Six bucks and I'm back in action. I am only average handy, so anybody with a little talent can do this. I took the bottom front cover off first. Then opened the door and took the cover on the inside off. When you do this, you will have to disconnect wires from the door switch and inside light. Don't worry about it, they are pretty easy to remember what goes where, but if your scared, get little pieces of masking tape, write on it which connector it lands on, then tape it on the wire. The inside door cover will also take the vent and the connecting duct to the blower with it. You may have to wiggle the duct a little to get it off the blower. After that, I unfastened the top and lifted it back and out of the way. You should now be able to fully see the drum. No bolts, just slide it right out. If your belt is still around it, you may have to play with it a bit to get the tension off the belt. Once you got the drum out, you'll see the idler arm and pulley. I took the whole arm off (one nut and bolt) to make it easier to put the new pulley on. Once off, the hardest part of the job was to get the retaining ring off. If you got the right tool, it would be no sweat, but I didn't want to go to town, so I used two pairs of needle nose pliers to get it apart. New pulley slides right on, however, I would advise cleaning off any hardened grease on the idler arm connection and putting new grease on it. Put everything back together in reverse order. The belt can be a little tricky, but they have an awesome video on here, and once I watched it, had the belt on in 5 minutes. Buttoned everything back up just in time for kickoff. About an hour and a half work, less if I had the right tool to get the retaining ring off.

Parts Used:

-

Jeremy from Soddy Daisy, TN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Belt cut in two

First I take off all front cover and then the dirt strainer next is the dryer drum holder next the top cover I lift up and so you room to set the dum belt

Parts Used:

-

Herminigildo from virginia beach, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

Was this instruction helpful to you?

Thank you for voting!

Broken drive belt

I was amazed just how easy it was. It would have been much quicker if I had a nut driver instead of a wrench. The video was great. Thank you!

Parts Used:

-

chris from bakersfield, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Wrench set

Was this instruction helpful to you?

Thank you for voting!

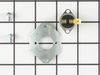

No heat

I feel like I have a new dryer now. I replace 3 of the 4 main components using parts select. Not only did they ship next day, but the tutorial videos with Steven were right on the money and self explanative.

Parts Used:

-

Steven from Oak Lawn, IL

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

thumping with each rotation

As you see I replaced ALL these parts, not because they were broken but some were a little worn and while I had it apart, might as well do a total maintenance job. Could not at first figure out the thumbing, but while inspecting, notice the belt was almost cut thru, could have gone at any time, one drum support roller was dragging as well as the idler pulley wheel. Could have sanded down all the axles for each wheel but might would have too much play after Also cleaned every part and nook and cranny while all was apart. Put everything together and it still....thumped. While running I held a flashlight underneath and around every part, and finally found the issue. The very back of the tumbler had a hair line crack about one inch long, causing the two pieces of metal to get in a bine while at the bottom of the rotation exactly between the two rollers. Soooooo, at 450.00 for a new one, I just used a screw driver, steel punch and hammer to mold in like I wanted and it quit making any nosy, applied HD steel tape on both sides so the crack will not catch cloths while drying and presto redneck engineering at its best...no more thumping and is as quite as the day we bought it, and since cleaning out all the internal ducks it dries much better and faster. Otta last several more years, yaha.

Parts Used:

-

Don from Haslet, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

drum noisy then quit turning

Disconnect power supply. remove two 5/16" machine screws from bottom front cover, pull out and down cover will pop out. open door and remove lint screen. Remove screws from top of dryer and pop it off and get out of the way. Now remove front panel and lint screen body. there are screws inside of dryer for screen body. Make sure to take photos of wires or make a diagram so you put them back correctly. Now you can remove drum and see pulleys. This is all pretty self-explanatory. Just re-assemble in reverse. Whole project takes maybe 45 minutes.

Parts Used:

-

lance from festus, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Tumble but NO HEAT !

I followed common causes list for this problems from website. It is described that the coils are the most common reason then a list of other parts including High temperature fuse, thermostat, High limit temperature fuse, etc. Replace all these and problem remained unsolved. I search other website and found out that 9/10 times this problem is caused by a blown <<- IGNITER ->>. I inspected and indeed that was the problem. It is PITY that "Partselct" did not display this common cause just because they don't have this part available. I expended about $100 in unnecessary parts. Thank you very much !!!

Parts Used:

-

Santos from Rialto, CA

-

Difficulty Level:Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!