DBL333GA0WW General Electric Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

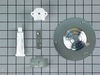

Replaced broken START knob on dryer.

Slid off the old START knob, then pushed on the new START knob.

I created and printed a label on my computer for use with the time selector dial, which must be set at or beyond 10 minutes, before turning the START knob.

I made a label that says "Minimum" with a red arrow that points past the 10 minute setting on the time selector dial.

My teenage daughter was not setting the time selector dial, to a point past 10 minutes. When she turned the START knob, the dryer would not come on, because the time selector dial was not set past the 10 minute setting.

My daughter had continually twisted the START knob until it broke. I am hoping she will be able to see the large printed label I put on the dryer near the time selector, saying "Minimum" with a large red arrow pointing past 10 minutes.

I am very pleased that I was quickly able to find the exact matching START knob for my dryer and the exact same color, from PartSelect.Com

I created and printed a label on my computer for use with the time selector dial, which must be set at or beyond 10 minutes, before turning the START knob.

I made a label that says "Minimum" with a red arrow that points past the 10 minute setting on the time selector dial.

My teenage daughter was not setting the time selector dial, to a point past 10 minutes. When she turned the START knob, the dryer would not come on, because the time selector dial was not set past the 10 minute setting.

My daughter had continually twisted the START knob until it broke. I am hoping she will be able to see the large printed label I put on the dryer near the time selector, saying "Minimum" with a large red arrow pointing past 10 minutes.

I am very pleased that I was quickly able to find the exact matching START knob for my dryer and the exact same color, from PartSelect.Com

Parts Used:

-

SAM from ROCK HILL, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

502 of 513 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The inside of the Selector Knob was stripped

Removed the damaged knob and replaced it with the new knob. Very ease

Parts Used:

-

Frank from Irvine, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

383 of 389 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Knob Post

First I unplugged the dryer, then I removed the access panel on the back of the control panel. I removed the wires from the back of the switch...Here is where I messed up. I removed the switch prior to ordering the part, the bad part is the way I removed the part. When you get the new part in you will be able to see how it will be mounted to the control panel. I had no idea, so I did what was necessary to remove it. Needless to say, I bent the hell out of the hole that the switch mounts in. In turn, the installation of the new switch did not go as easily as I would have liked. After straightening out some metal and drowning the thing in epoxy, the new switch is installed. I hooked the wires back up on the back of the switch, plug in the dryer, and dry some clothes. Standing victorious over the dryer with beer in hand, not only did I accomplish the mission but I learned my lesson... destructive removal = BAD!

Parts Used:

-

Jaren from Lemoore, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

122 of 142 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud noise & clothes hanging in drum.

1. Remove power cord from wall outlet. Unlatched the top lid of the dryer by pushing a flat screwdriver under the R & L sides where a metal clip on each side holds the top down.

2. Removed the yellow clip screwed onto the top frame.

3. Removed the front frame of the dryer by unscrewing the two screws holding the front frame on – one on either side.

4. Mark w/ an (x) on same side of alignment for the 2 wiring connectors before separating them.

5. Removed the front panel by tilting it forward & lifted to unlatch it from the 2 clips at the bottom of dryer.

6. Unwound the belt encircling the drum by releasing the tension between the tensioner roller & drive pulley. (Its better to remove back access panel at this time & do this at the back since I found it necessary to do this anyway when re-installing the new belt).

7. W/ lifting motion, pulled the drum out from the plastic holder attached to the back of the dryer frame. Guided & completely removed the drum out of the dryer.

8. Unscrewed the 3 screws holding the old big bearing to the back of the drum.

8. Unscrewed the 2 screws & removed the plastic that had held the bearing at back of the frame.

8. Installed the new bearing by screwing it to the back of the drum with 3 screws. Be careful not to strip screws. Used help to hold new bearing in place & aligned w/ screws.

9. From the front, installed the plastic holder to the back of the frame by 2 screws and put the ball bearing in-between holder & the metal strip retainer coming from the back of dryer.

10. Used the grease that came with the kit on the plastic holder & the big bearing at the back of the drum.

11. Replaced w/ new belt then re-inserted the drum back into the body of the dryer frame, w/ lifting motion, re-inserted the bearing into the plastic holder.

12. Putting the belt into the drive & tension pulleys through the back access panel was easy but could be very hard to do if coming from the front.

13. Had to replace the front panel's top felt w/ glides that holds the drum at the front w/ a new one. Really important to pay attention to where the plastic glides excess portion is facing (towards front panel), otherwise the front panel might not fit when you snap it back to place.

14. Removed old felt remnants w/ blade scraper & sandpaper. Used adhesive that came w/ kit. Once tacky, put the new felt w/ glides on & used clamps to hold it in place.

15. Waited for 2 hrs. (watched a movie) then re-installed front panel. Make sure that the drum (front) lid rides on top of the plastic glides.

16. Latched bottom of front panel to the metal clips. Replace the 2 screws back into place holding the front panel.

17. Snapped the wiring connectors in place where the (x) marks align.

18. Lowered the top panel & snapped it back into place

Note: All parts came w/ fast delivery & OEM fit - very satisfied! Took my time & on every chance I cleaned & vacuumed all areas of lint & dirt since the dryer hasn't been serviced for more than 10 years...

2. Removed the yellow clip screwed onto the top frame.

3. Removed the front frame of the dryer by unscrewing the two screws holding the front frame on – one on either side.

4. Mark w/ an (x) on same side of alignment for the 2 wiring connectors before separating them.

5. Removed the front panel by tilting it forward & lifted to unlatch it from the 2 clips at the bottom of dryer.

6. Unwound the belt encircling the drum by releasing the tension between the tensioner roller & drive pulley. (Its better to remove back access panel at this time & do this at the back since I found it necessary to do this anyway when re-installing the new belt).

7. W/ lifting motion, pulled the drum out from the plastic holder attached to the back of the dryer frame. Guided & completely removed the drum out of the dryer.

8. Unscrewed the 3 screws holding the old big bearing to the back of the drum.

8. Unscrewed the 2 screws & removed the plastic that had held the bearing at back of the frame.

8. Installed the new bearing by screwing it to the back of the drum with 3 screws. Be careful not to strip screws. Used help to hold new bearing in place & aligned w/ screws.

9. From the front, installed the plastic holder to the back of the frame by 2 screws and put the ball bearing in-between holder & the metal strip retainer coming from the back of dryer.

10. Used the grease that came with the kit on the plastic holder & the big bearing at the back of the drum.

11. Replaced w/ new belt then re-inserted the drum back into the body of the dryer frame, w/ lifting motion, re-inserted the bearing into the plastic holder.

12. Putting the belt into the drive & tension pulleys through the back access panel was easy but could be very hard to do if coming from the front.

13. Had to replace the front panel's top felt w/ glides that holds the drum at the front w/ a new one. Really important to pay attention to where the plastic glides excess portion is facing (towards front panel), otherwise the front panel might not fit when you snap it back to place.

14. Removed old felt remnants w/ blade scraper & sandpaper. Used adhesive that came w/ kit. Once tacky, put the new felt w/ glides on & used clamps to hold it in place.

15. Waited for 2 hrs. (watched a movie) then re-installed front panel. Make sure that the drum (front) lid rides on top of the plastic glides.

16. Latched bottom of front panel to the metal clips. Replace the 2 screws back into place holding the front panel.

17. Snapped the wiring connectors in place where the (x) marks align.

18. Lowered the top panel & snapped it back into place

Note: All parts came w/ fast delivery & OEM fit - very satisfied! Took my time & on every chance I cleaned & vacuumed all areas of lint & dirt since the dryer hasn't been serviced for more than 10 years...

Parts Used:

-

Raul from Fountain, CO

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

79 of 84 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Start Rotary Shaft stripped

One of the easiest repair jobs I've ever done. First I turned off the power. After removing 4 screws and lowering the cover of the control board, I disconnected the two wires attached to the switch. I rotated the switch counterclockwise and removed it. Just reverse this process and I was done. I was in and out in less than 10 minutes.

Parts Used:

-

Neil from Doylestown, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

90 of 158 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

selector knob cracked

ordered part on line--received in mail 2 days later--

just pushed on in 2 seconds--job done

how much easier can it get??????

just pushed on in 2 seconds--job done

how much easier can it get??????

Parts Used:

-

William from West End, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

74 of 136 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud rhythmic squeaking

About a year ago I had to replace the front sliders. I had thought at the time that I should replace the belt and check the rear bearing, but I was in a hurry, and the wash was backing up, so I didn't do it. Oops. Within 6 months dryer started squeaking. Did I get around to pulling it out, and greasing rear bearing. Nope. Dbl oops.

Luckily on this model, everything is pretty basic, strong, and well made. The rear bearing after 9 years of constant use (5 person family)had simply run out of grease, and then worn into the plastic housing that holds the rear bearing. NOTE TO ALL -- probably too late if you're reading this -- but just grease your rear bearing by using a grease gun with high temp grease (car bearing grease works fine)through the small hole at back of dryer dead center of drum. It will take 5 min, and probably prevent the need for this repair, or delay it substantially.

Unplug dryer, turn off gas, and disconnect gas hose and duct hose. Inspect the latter two and consider repacing while you're at it. Move dryer to where you can get at front and back without cursing too much.

So...take a putty knife, and put a little masking tape around the blade if you're worried about scratching the finish on your dryer. If you're doing this repair, your dryer is probably at least as old as mine, and you can skip the tape and just bear with some small scratches.

Slide the putty knife into the groove between lid and front of dryer and pop up. (held by spring clips)

Now tip up lid and slide back, you may have to wrestle it a bit, or it may come off like a charm. Put it out of the way.

Take a sec to look at the interior wiring (you unplugged the dryer, right?) If you see any worn or raw spots, take some electrical tape and fix. Should be fine though. Take a vacuum and suck up any extraneous lint, dirt etc.

Tip dryer up slightly and block with wood or a brick. There are two screws at bottom -- undo these. IF they're missing, no worries, they're not critical. Put dryer back down.

Get a trouble light or a good lamp and shine ti wher you can see interior of dryer. There are two screws, one on each side on the INSIDE of the dryer, connecting the side panels to the front. Undo those. Put them in a little baggie and mark them "interior fr screws." I know, you're thinking "I can just remember them." But trust me, this way, you can't lose them or screw up. Now use the putty knife to pop the front panel off the sides. Do this gently, and don't yank the front way back, as the drum will drop. Oh, on mine there was a yellow plastic doohicky in the middle at top. Take that off too (one tiny screw) put the screw back in part way and stick the doohicky in the baggie.

OK, so the front panel should now be loose. It is still on a couple of little tabs at the bottom, which you prefer not to bend. So lift the front slightly and then back it out, while you (or preferably a helper) holds the drum so you can let it down gently. The front is attached to all sorts of wiring. You don't need to disconnect ANYTHING. THe front should be able to be moved away to the right like a door. Rest this up against something so as to not strain the wiring. On the front of the door are the felt and plastic sliders. If they look beat up or worn, replace them now -- or like me, you can do the job twice... That part is super simple...

Now, got back of dryer, there is a vent at back bottom. Remove three (or less) screws) and remove little door. Probably substantial lint here. Vacuum like crazy. The belt comes down around the drive pulley, and then up and over the idler pulley (to keep tension on belt. IF this feels loose/easy to move, replace the belt. In fact, if the belt is over 5 years old, replace the belt. (or when it breaks, you get to open everything again). Just unhook the spring and the idler will be loose and you can remove the belt off the pulleys -- it's now just around the drum. Slide the idler pulley off the stem

Luckily on this model, everything is pretty basic, strong, and well made. The rear bearing after 9 years of constant use (5 person family)had simply run out of grease, and then worn into the plastic housing that holds the rear bearing. NOTE TO ALL -- probably too late if you're reading this -- but just grease your rear bearing by using a grease gun with high temp grease (car bearing grease works fine)through the small hole at back of dryer dead center of drum. It will take 5 min, and probably prevent the need for this repair, or delay it substantially.

Unplug dryer, turn off gas, and disconnect gas hose and duct hose. Inspect the latter two and consider repacing while you're at it. Move dryer to where you can get at front and back without cursing too much.

So...take a putty knife, and put a little masking tape around the blade if you're worried about scratching the finish on your dryer. If you're doing this repair, your dryer is probably at least as old as mine, and you can skip the tape and just bear with some small scratches.

Slide the putty knife into the groove between lid and front of dryer and pop up. (held by spring clips)

Now tip up lid and slide back, you may have to wrestle it a bit, or it may come off like a charm. Put it out of the way.

Take a sec to look at the interior wiring (you unplugged the dryer, right?) If you see any worn or raw spots, take some electrical tape and fix. Should be fine though. Take a vacuum and suck up any extraneous lint, dirt etc.

Tip dryer up slightly and block with wood or a brick. There are two screws at bottom -- undo these. IF they're missing, no worries, they're not critical. Put dryer back down.

Get a trouble light or a good lamp and shine ti wher you can see interior of dryer. There are two screws, one on each side on the INSIDE of the dryer, connecting the side panels to the front. Undo those. Put them in a little baggie and mark them "interior fr screws." I know, you're thinking "I can just remember them." But trust me, this way, you can't lose them or screw up. Now use the putty knife to pop the front panel off the sides. Do this gently, and don't yank the front way back, as the drum will drop. Oh, on mine there was a yellow plastic doohicky in the middle at top. Take that off too (one tiny screw) put the screw back in part way and stick the doohicky in the baggie.

OK, so the front panel should now be loose. It is still on a couple of little tabs at the bottom, which you prefer not to bend. So lift the front slightly and then back it out, while you (or preferably a helper) holds the drum so you can let it down gently. The front is attached to all sorts of wiring. You don't need to disconnect ANYTHING. THe front should be able to be moved away to the right like a door. Rest this up against something so as to not strain the wiring. On the front of the door are the felt and plastic sliders. If they look beat up or worn, replace them now -- or like me, you can do the job twice... That part is super simple...

Now, got back of dryer, there is a vent at back bottom. Remove three (or less) screws) and remove little door. Probably substantial lint here. Vacuum like crazy. The belt comes down around the drive pulley, and then up and over the idler pulley (to keep tension on belt. IF this feels loose/easy to move, replace the belt. In fact, if the belt is over 5 years old, replace the belt. (or when it breaks, you get to open everything again). Just unhook the spring and the idler will be loose and you can remove the belt off the pulleys -- it's now just around the drum. Slide the idler pulley off the stem

Parts Used:

-

Mark from San Diego, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

44 of 53 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start

The switch made a humming sound when I turned it so I thought that might be the problem. Using the instructions on this Web site I took the top panel of the dryer off (after unplugging it), unplugged two wires leading from the switch (needed pliers for this), and removed the switch unit by rotating it counterclockwise (when behind it).

The replacement part came in two days. The installation went a lot quicker-maybe ten minutes.

The replacement part came in two days. The installation went a lot quicker-maybe ten minutes.

Parts Used:

-

Ray from Kingwood, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

33 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Switch knob and shaft broke off from using pliers.

Unplugged dryer. Removed screws from top of operating panel. Removed wires from switch. Turned switch 1/4 turn to left and removed. Replaced switch. Turned 1/4 to the right. Re-attached wires. Replaced operating panel and screws. Replaced knob. Plugged in dryer. DONE!!!!!!

Easiest repair ever! Thank you.

Easiest repair ever! Thank you.

Parts Used:

-

robert from ossineke, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

19 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

loud squeak/burnt edges of clothes

I used the puddy knife at the top of the front panel seam. I pushed in the knife till I heard the top panel release. I then did the other side of the front panel till I heard the same sound.I now could raise the top of the dryer. Inside the front panel(on the left and the right) are two philips head screws that I loosened and took off, releasing the front panel,however I had to use the needle-nose pliers to take off two electr. connections to the door switch. After I took off the front panel, there it was ,THE PROBLEM. The top glide and bottom felt were shot and worn out. I did as the directions told me, and with a 1" chissal, I gently scraped off the old glide and felt, without scratching the metal. Cleaned off the residue of old glue with Goo-Gone. Now I put glue on the top part of the portal(which I marked before I removed it) waited a minute for it to get tacky and layed the new top glide on, gently pressing down to insure adhesion. It dried right away. I did the same with the lower felt glide.I did all the reinstallation of the panels in reverse order and everything fit perfectly and smoothly. I waited about an hour to make sure all was dried (glue) and turned it on.It was alittle stiff running at first, but then it ran smooth as silk and no more squeaking or burning of my clothes.Thank you partselect!!!!

Parts Used:

-

Philip from Irmo, SC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

15 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Start Switch stick (plastic thing that pops out) was broken

Removed 6 screws from the back panel and lifted/pushed the metal back panel up. Removed/sliced out the start switch by hand. Replace the new start switch and tightened all screws. Replaced the new selector Knob and it worked like charm.

Parts Used:

-

Kusuma from Alpharetta, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench (Adjustable)

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replace knob

-

Gerald from Chino, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

11 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squeeling when on

Most time was spent on web looking for disassembly diagrams! But once I got it apart it was good. And I saved about $27.00 buying from this site! Putting together was easy, clamping down felt with glue on it so it would dry right and then putting front on with drum riding on the glid was the hardest. I also put synthetic grease on rear bearing. Fired it up after repair and my wife is back dring clothes again! Products were at my door 3 days after ordering at 11:30 pm at night!

Parts Used:

-

BRENT from ST.AUGUSTA, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

15 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud screeching noises from the rear of the dryer whenever in was running.

We unlatched the top of the dryer by pushing a screwdriver under the two areas where there were metal clips holding it down. We then removed the yellow clip screwed onto the top frame. We removed the front frame of the dryer by unscrewing the two screws holding the front frame on--one on either side. We didn't undo the wiring to the controls, we just kind of pivoted the front aside. We pulled the drum out from the plastic holder attached to the back of the dryer frame also unwinding the belt encircling the drum. Then we unscrewed the 3 screws holding the bearing to the back of the drum. We removed the plastic that had held the bearing by undoing the screws to the back of the frame. We installed the new bearing by screwing it to the back of the drum with 3 screws. We installed the plastic holder to the back of the frame by 2 screws and put the little ball bearing in. We used the grease that came with the kit to grease up the plastic where it held the big bearing attached to the back of the drum and inserted the drum back into the body of the dryer frame, pushing the bearing into the plastic holder. The hard part was getting the belt back around the drum and through the pulley on the motor that holds the belt. When that was accomplished, we put the yellow plastic holder back on the front frame with the screws and put the front back on after thoroughly cleaning the inside bottom area where there was a lot of lint. Then we snapped the top back into place.

Parts Used:

-

Kenneth from Boise, ID

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

11 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Plastic stem that the knob attaches to, broke off

unscrewed the back plate off of the dryer. Disconnected the the wires off of the switch. Remember to to unplug your dryer from the wall first!!!. Reconnect the wires to the new switch and twist back into place. Be careful not to bend the metal tabs. Put the back plate back on and plug in. Put on new knob and the wife was smiling. Took about 8 minutes to repair.

Parts Used:

-

lee from port charlotte, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!