CADE165SAL General Electric Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

original equipment belt-drive broke

disassembled chassis of dryer, unbolted top, lifted top to expose drum. bolted top back on. resumed repair next morning. unbolted top. lifted drum (it moved up and down about 1 inch) and got new belt around it. rebolted top down. tipped dryer to its back. unbolted and removed panel at bottom, exposing drive motor and tensioner spring. positioned belt around drive motor spindle and tensioner spring. replaced panel. reconnected dryer to electricity. reconnected gas using new flexible connector.

Parts Used:

-

james from chicago, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

noise when running

found a bad heating element upon dissassembly had to remove drum to get to bearing.removed heating element coil and housing to replace bearing assembly.reassemble unit and test

Parts Used:

-

Charles from Parish, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

dryer door would not stay closed

-

Dave from Redondo Beach, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

The main symptom was a burning smell that got on the clothes and the dryer was somewhat louder than it had been.

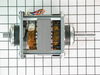

Researching on the web I thought the trouble might be lint buildup or trouble w/ one of the parts involved in spinning the drum. However I cleaned out all the lint and replaced the belt and idler pulley and this didn't improve the smell (drum bearing was fine). I then concluded the trouble was the motor. Running the motor w/o the drum in place confirmed this was where the noise/smell was coming from. Replacing the motor was fiddly--I had to remove the clip holding the motor (pried the top w/ a screwdriver), wires (made a diagram so as to put back in same order, they were hard to get off--a pliers did the job), clamps holding the motor on the duct, the motor mount, the duct, the fan. Putting all this back together took a while (not hard just fiddly). Tested the motor w/out the drum in place and it sounded fine. Put the drum and back/front/top panels back and the dryer runs fine now. All parts came quickly and exactly matched the parts in my 1993 Hotpoint dryer. As others have said the pulley kit is not needed--these are included w/ the motor. BTW I am a 53-year-old lady. Thanks to all who took the time to write up their experiences--big help!!

Parts Used:

-

Kristin from Bellevue, WA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

drum bearing shot

sort of followed instructions, would have beenhelpfull if they told me I HAD TO REACH INTO THE MOUTH OF A SABRE TOOTHED TIGER to install the new belt.

Parts Used:

-

Dennis from Yakima, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

Was this instruction helpful to you?

Thank you for voting!

Holes were not threaded on rear bearing kit

Had to tap three holes in the rear bearing to match the three attachment screws. Screw up with the part.

Parts Used:

-

Dennis G from Naples, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

Was this instruction helpful to you?

Thank you for voting!

The drum stopped turning in the dryer

Based on the symptom (drum not turning), I figured that the belt was shot. I found a video on YouTube that described how to fix it. I also found directions here on this site on how to fix it! Here's what I did: step1: there were two screws holding the top on. took them off and the top swung up, exposing the drum and broken belt. step2: took off the two screws holding the front on. tipped the front forward so I could get the new belt around the drum. step 3: took the back plate off (10 screws). had to remove the exhaust tube first. cleaned out all the lint with the shop vac. there was plenty of lint everywhere. step 4: put the belt onto the motor pulley wrapping around the tension pulley. step5: put everything back together and plugged it in. everything worked fine. it took longer to vacuum all the lint out than it did for the actual repair.

Parts Used:

-

Alan from Wheaton, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

temperature in dryer erratic.

removed four screws holding top. Swing back top to expose thermostat. emove two push on connectors and two self tapping screws. Instal new thermostat

Parts Used:

-

Robert from Palm Harbor, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

Loud Squeek When Started until warmed-up

Ordered the recommended parts on-line and they showed up the next day. I followed the on-line repair video that described it all step-by-step.

Parts Used:

-

David from Oregon, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

bearigs,belt squeak

Unscrewed the top lid screws located in door opening.Removed lid.Unscrewed the front cover screws located at top corners of cover, underneath where the top lid was.Pulled out drum,removing belt at same time.Removed the rear bearing unit,installed new one.Really easy.Took front bearing off front cover,it just snaps on.Installed new bearing,with 4 new slides.Reassembled machine,replacing old belt at the same time.Done.It really is that easy.Spent more time cleaning lint out of dryer interior than actual mechanical work,I think.

Parts Used:

-

TIM from NORTH AURORA, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Drum was not turning

This is the third time for a belt on this 28 year old dryer. Not too much to it. Unplug the dryer. Open the door. Remove the screws holding on the front panel and loosen the screw at the bottom. Disconnect the wires to the door switch and lift off the front panel and start up the shop vac to clean out the lint - there is a lot to be found in various places. Slide the new belt over the front of the drum and make sure there are no twists. You can now reverse the order to mounte the front panel but don't close the top so you have light to see inside. Go around to the back panel and remove the machine bolts holding on the access panel at the back. This allows access to the motor and belt tensioner. Get the shop vac out here and get to some more lint. Google the model number to find a diagram on how to route the belt. Put the belt on the motor shaft and around the tensioner as depicted. Occaisionally the plastic idler pully is worn and this can be the cause of the brokent belt. If the idler wheel does not spin freely, squeads or is cracked it should be replaced or you will be right back replacing the belt again. If all is fine it is time for a test run. CAUTION - you can plug the dryer in but keep your hands out of the cabinet as there are live exposed 220 volt terminals exposed. This allows you to observe that all is working and not binding during a test run with NO heat. If all is fine, unplug the dryer and put the covers back on. Reconnect the exhaust hose (now is a good time to clean that and the vent to outdoors as well).

Parts Used:

-

David from Dublin, OH

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Broken Belt

I was unsure of how to disassemble the machine to reach the belt, but a YouTube video gave me confidence. Thanks to Partselect.com, the great customer service, and fast delivery. I had my dryer up and running really fast! The process was really not difficult at all and it gave me a chance to vacuum out years of trapped lint. I am so happy to have saved hundreds of dollars, not having to buy a new dryer.I would urge other folks to tackle these relatively simple repairs, the right parts are a phone call away. Frank

Parts Used:

-

Frank from Norwalk, CT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

broken belt

unscrewed and lifted top of dryer put belt around drum closed top put belt around motor pulley and belt tensioner and finished.( remember to unplug unit before working on it.)

Parts Used:

-

Dennis from Hamburg, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Broken belt

I didn't know what was wrong at first, only that the dryer would not start. I bought it used so had no fear of taking it apart to diagnose. Found the broken belt inside, ordered a replacement, installed the new belt, then crossed my fingers. Was pleasantly surprised that was all that was wrong and that for less than $20, including shipping, a few hours of my time, and a little help from YouTube videos the dryer is working again!

Parts Used:

-

Kevin from Simi Valley, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Knocking with sqealing when operating

The same procedures as posted in the video, but as applied to the model. Belt had broken. Bearing and front supports were worn, but the cause of the noise was a worn tensioner pulley bearing/arm, causing damage to the belt until breakage. Save the time and effort of a second repair and purchase a tensioner arm/pulley anytime the belt breaks as this is likely the cause of the original breakage. The hardest part on this older GE was getting under the drum to engage the tensioner and belt to the motor, as clearances we very tight. Review the diagrams, watch the video, and enjoy a quiet and well running machine for your efforts. PartsSelect is the only place to shop for appliance parts, my hat's off to excellent service, fair pricing and fast shipment. Thanks PartSelect!

Parts Used:

-

Barry from Newport, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!