AGM459 Speed Queen Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Gas flame would not relight after it reached its first heat cycle.

I removed the two spade connectors and then removed the two 1/4" hex screws. I then simply removed the defective unit and replaced it with the new on and re-installed the two screws and wires.

This was not the problem though.

I turned out to be the solenoids on the gas valve.

This was not the problem though.

I turned out to be the solenoids on the gas valve.

Parts Used:

-

David from Humble, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer made a random grinding/rubbing noise during operation.

After removing the lower access panel, I observed the drum and belt and saw it turning freely. The support rollers in the back turned freely and were in good condition as well. At odd intervals the unit made a humming or grinding noise, and i decided to check the blower wheel (the other rotating part in the system). I found that the central hub of the wheel (which is made of a nylon like plastic) had sheared off from the wheel itself. I ordered a new part and started to remove the old wheel. **NOTE** many of the stories I read described how this part would have a reverse thread, it did not and that cost me an extra 30 minutes to figure out (the new part had arrows showing the correct direction to put on and remove - the original didn't). Once everything was cleaned and reassembled, I started the dryer again, but got no heat. I had previously replaced the heating element, so I thought my wiring was wrong. That wasn't the problem, but a hint from this site about checking the incoming wiring was the solution, my ground wire had come off the terminal in the back of the dryer and I wasn't getting the volatge across the element that it required. With the ground wire back in place, everything worked fine.

Parts Used:

-

Timothy from Hardeeville, SC

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squealing idler pulley

Propped the machine up in the front, removed the front panel, the door assembly, and the front drum support. Use a Sharpie to mark wire positions. This will help during re-assembly. To get the drum out, you first have to remove the belt from the motor pulley. Drum slides right out. You will need snap-ring pliers to remove the pulley from the idler arm. I also replaced the drive belt because it was cheap, and always a good idea to replace it when you are this far into the machine if it is a few years old. Re-assemble in the reverse order of disassembly. An easy fix for the average do-it-yourself person.

Parts Used:

-

Dave from Brighton, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Button to start dryer

Per instructions I printed off online: took off door, then the front panel. Pulled out the old switch/button, connected the new switch/button, made sure the new button was working; put the panel back on then the door and DONE!

Parts Used:

-

Loretta E. from Miamisburg, OH

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

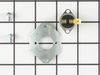

Dryer would heat up at start then go cool

Really an easy fix. 2 5/16" screws hold the cover on below the dryer door. From here it's easy access to the gas element. 2 more screws for the valve cover and disconnected the attached wires to the gas coil valves. slip the news ones in place, re-attach the wires and install the holder.Tested the dryer and it fired right up. Put panel back in place and the wife is happy it didn't cost us more than just the parts. Yep, she's a lucky girl. ;0)

Parts Used:

-

Richard from Palos Hills, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Belt Was Broken

Unable to find a repair manual or accurate diagram, I forged ahead and removed the top and front panels of the dryer. It took two tries to figure out how to thread the belt (nine of my ten thumbs kept getting in the way!), but after a coffee break, the job came together, and I've taken the clothesline down!

Parts Used:

-

Richard from Kealakekua,, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

gas drier would not heat

i read some of previous customer problems and fixes pulled the front cover off found coil's location when i turned on drier you could see the ignitor getv hot but burner would not ignite unless i put a little pressure on secondary coil when i let go of coil flame would go out. ordered 'M' series new style coil kit came in in about three days installed parts drier workng good i would reuse parts select agian thanks

Parts Used:

-

DALE from HOPE HULL, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer did not get hot

Found on your site the top two causes of a Dryer not getting hot enough and ordered those parts ( which were delivered quickly).Removed the top two screws that hold the front of the dryer that gives access to the coils and flame sensor assembly after lifting up the top.It took more time to clean up all the lint than to replace the parts.Dryer works great!

Parts Used:

-

Garrett from Vineland, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not heat up

As many of the other posts here on this website mentioned, I had the same problem of the dryer not heating up. I removed the front panel (4 screws on each side inside of door - easy - followed instructions) and once off I was able to view the igniter glowing properly so I knew the starter/igniter was not the issue. Everything I read then suggested that it must be the two terminal gas valve coil, and sure enough it was. Ordered part -- got it in literally a couple days -- removed bracket (two screws) put in new coil -- turned it on -- works great. Could not have been easier. This is a great website and would recommend it to everyone who is a Do It Yourselfer.

Parts Used:

-

David from Naperville, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer not heating

Terminal Block was cracked and dryer was not receiving enough voltage, causing the heating element not to heat. Here were the steps I took to fix the problem:

1. Turn off breaker to dryer from 240v outlet

2. Unplug dryer from 240v wall outlet.

3. On outside, rear of dryer, remove cover plate and the clamp that the power cord goes through with nut driver or phillips screwdriver and take picture or write down how the power cord wires go to the terminal block.

4. Use nut driver or phillips screwdriver to remove the power cord wires from terminal block and ground wire from dryer body.

5. On top front of dryer, use large slotted screwdriver or some other tool to push in on the two clips in order to lift the cover up on dryer.

6. Take picture or write down how wires are attached to terminal block.

7. Remove wires from terminal block with nut driver or phillips screwdriver.

8. Use nut driver to remove terminal block from washer and install the new terminal block.

9. Reinstall wires to new terminal block.

10. Close dryer cover.

11. Reinstall clamp onto power cord wires and reinstall wires to new terminal block and ground wire to washer body then put cover plate back on.

12. Plug in dryer then turn on breaker.

13. Start dryer to see if it heats now.

1. Turn off breaker to dryer from 240v outlet

2. Unplug dryer from 240v wall outlet.

3. On outside, rear of dryer, remove cover plate and the clamp that the power cord goes through with nut driver or phillips screwdriver and take picture or write down how the power cord wires go to the terminal block.

4. Use nut driver or phillips screwdriver to remove the power cord wires from terminal block and ground wire from dryer body.

5. On top front of dryer, use large slotted screwdriver or some other tool to push in on the two clips in order to lift the cover up on dryer.

6. Take picture or write down how wires are attached to terminal block.

7. Remove wires from terminal block with nut driver or phillips screwdriver.

8. Use nut driver to remove terminal block from washer and install the new terminal block.

9. Reinstall wires to new terminal block.

10. Close dryer cover.

11. Reinstall clamp onto power cord wires and reinstall wires to new terminal block and ground wire to washer body then put cover plate back on.

12. Plug in dryer then turn on breaker.

13. Start dryer to see if it heats now.

Parts Used:

-

Henry from LA FOLLETTE, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas dryer would produce heat for short time, then continue to run but with no heat.

Thanks to reports from others, I concluded that most likely the gas ignition coils (one or both) were no longer functioning properly. I replaced both with the 'M' Series New Style Coil Kit which is about 1/2 the price of either coil individually -- yes,true,go figure! The actual replacement took only about 10 minutes. What was most difficult and took the most time was the removal of the front panel of the cabinet -- this was difficult only because there were no instructions in my owner's manual (or any other source I could find) and it took me awhile to figure it out. Now I could do the whole job in about 20 minutes! The detailed instructions from others as to the process of replacing the coils was invaluable -- I don't know if I would have been able to figure that out on my own. But most important was the information that enabled me to diagnose the problem in the first place. Thank you, all you previous comment contributors.

Parts Used:

-

James from Saint Paul, MN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

belt was cracking and dryer was somewhat noisy

I used your great video for pointers as to what to do. I took off the front, raised the top, vacuumed the whole thing up, that took quite a while. Took out the drum. Did more cleaning. Then took off the old retaining rings with retaining ring pliers, took off the old drum rollers and support. Replaced with new roller supports, washer, roller, washer and retaining rings. Then I replaced the belt. Tested it and turned the wrong way and it came off. Replaced and tested it again and I don't know why but it came off. Replaced the belt again, tested fine. Then I replaced the felt pads and glides, they were worn. I ended up asking my husband to help hold the drum so I could get the front back on. Replaced front and door. Tried the dryer. Works great AND very, very little noise. Note: when taking the wiring off the light and the door switch, I took photo's of those places with my cell phone and had them to look at to make sure the wiring was correct.

Parts Used:

-

Melody from Silverton, CO

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No heat in dryer. Gas would not come on.

Replaced the flame sensor and the igniter. Probably didn’t need the igniter but put in anyway. Saved old igniter for a later time just in case it burns out.

Parts Used:

-

Stephen from Lilburn, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum stopped turning, motor still running

Dryer stopped tumbling, so bad belt was my first thought. Dryer is in vacation home so did not have immediate access to it to diagnose. Ordered belt and discovered that the poorly designed motor pulley had broken and the belt jumped onto the motor shaft and burned through the original belt. Week 2 after ordering pulley, installation went per YouTube video. Glad I also replaced the belt because it was brittle and cracked. Suspect it had been slipping because sheets would ball up into a log, possibly because the drum wasn't spinning fast enough. Anyhoo, after repair all seems OK.

Parts Used:

-

Richard from PORTLAND, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squeeling noise & drum turning real slow

unplug appliance.removed 2 screws @ the rear of dryer top to tip lid back. unplugged the door switch wires.took out 3 philip screws that hold lint screen to inside of drum.removed 2 screws @ dryer front top. lifted dryer front panel off. the drum was now loose. slipped off old belt - replaced with new. set drum back into place. made sure new belt was on motor pulley & behind tensioner pulley arm. replace & reconnect items in reverse order. plug back in & test. after seeing the wear on the plastic tensioner pulley i regret not ordering that part for replacement also.

Parts Used:

-

roy from tunkhannock, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!