A613 Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Clamp rusted through permitting upper & lower tub to separate

Clamp was already in multiple pieces so easy to get off.

Got clamp from partselect.com in 1 day which was great.

Removed two PH screws from front cover then pulled bottom of front cover outward and down to remove.

Caution for those doing this: take a piece of 220 or 240 grit paper and sand all the edges of the clamp. Trying to put it on without doing so will result in countless paper cuts in hands.

Before putting new clamp on be sure to use either some soap or silicon lube on the rubber V seal between upper and lover tub.

Also need to put some 1/4" to 3/8" spacers at three equally spaced places beneath the upper tub and the lower tub. If this isn't done the upper tub will drop down too far inside the lower tub and the inner lower tub, when it starts to spin, will rub on the underside of the upper tub = cause the main drive belt to smoke and tub to "freeze up"

Spacers I used were simply 3 pieces of multi strand sheathed electrical wire 3/8" so that I could bend them down at an angle and put them out once clamp was in place. Wire pieces need to be about 4-5" long.

Assemble one bolt in clamp and thread around tub in CCW direction.

Position one bolt of the clamp in right rear corner. this is important so that when tub goes out of balance, there's clearance for the clamp bolts and they don't contact the cabinet.

Make sure before threading clamp arount tub that the screw that will end up in the front left corner has a hex head on it so that you can apply some clamping "muscle" with a socket wrench.

I had trouble getting the front left screw inserted in the clamp (its only 2" long) so I used a 3" bolt to make the preliminary connection to pull the clamp semi tight. I planned ahead and got a light wire coat hanger to use as a "tie-tie" in the event that I had to remove the 3" slotted screw to revert back to the 2" hex head screw. Luckily when I removed the 3" screw I was able to quickly pop the 2" hex head back in and tighten completely.

Before putting front cover on, do one load with front cover off to make sure that upper and lower/inner tub don't rub each other.

If ok, turn power back off and put front cover back on.

Note: Would advised ordering the rubber V-seal if you are ordreing the clamp. If you buy the seal there are four bolts in the lid that let you lift the lid to work on the tub, clamp and seal MUCH more easily. Sticky part is getting water fill tube in top left rear disconnected so that new rubber v-seal can slide over tub.

Note also that in order to get to front left lid bolt that single bolt holding diaphram onto front left upright must be removed so as the let diaphram assembly drop away to access front left lid bolt. The two bolts in the rear can be accessed from the top very easily. Also need to disconnect the bleach fill tube in order to lift the lid (right side lifts up to vertical position)

Got clamp from partselect.com in 1 day which was great.

Removed two PH screws from front cover then pulled bottom of front cover outward and down to remove.

Caution for those doing this: take a piece of 220 or 240 grit paper and sand all the edges of the clamp. Trying to put it on without doing so will result in countless paper cuts in hands.

Before putting new clamp on be sure to use either some soap or silicon lube on the rubber V seal between upper and lover tub.

Also need to put some 1/4" to 3/8" spacers at three equally spaced places beneath the upper tub and the lower tub. If this isn't done the upper tub will drop down too far inside the lower tub and the inner lower tub, when it starts to spin, will rub on the underside of the upper tub = cause the main drive belt to smoke and tub to "freeze up"

Spacers I used were simply 3 pieces of multi strand sheathed electrical wire 3/8" so that I could bend them down at an angle and put them out once clamp was in place. Wire pieces need to be about 4-5" long.

Assemble one bolt in clamp and thread around tub in CCW direction.

Position one bolt of the clamp in right rear corner. this is important so that when tub goes out of balance, there's clearance for the clamp bolts and they don't contact the cabinet.

Make sure before threading clamp arount tub that the screw that will end up in the front left corner has a hex head on it so that you can apply some clamping "muscle" with a socket wrench.

I had trouble getting the front left screw inserted in the clamp (its only 2" long) so I used a 3" bolt to make the preliminary connection to pull the clamp semi tight. I planned ahead and got a light wire coat hanger to use as a "tie-tie" in the event that I had to remove the 3" slotted screw to revert back to the 2" hex head screw. Luckily when I removed the 3" screw I was able to quickly pop the 2" hex head back in and tighten completely.

Before putting front cover on, do one load with front cover off to make sure that upper and lower/inner tub don't rub each other.

If ok, turn power back off and put front cover back on.

Note: Would advised ordering the rubber V-seal if you are ordreing the clamp. If you buy the seal there are four bolts in the lid that let you lift the lid to work on the tub, clamp and seal MUCH more easily. Sticky part is getting water fill tube in top left rear disconnected so that new rubber v-seal can slide over tub.

Note also that in order to get to front left lid bolt that single bolt holding diaphram onto front left upright must be removed so as the let diaphram assembly drop away to access front left lid bolt. The two bolts in the rear can be accessed from the top very easily. Also need to disconnect the bleach fill tube in order to lift the lid (right side lifts up to vertical position)

Parts Used:

-

George from Fort Myers Beach, FL

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set, Wrench (Adjustable), Wrench set

27 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heard squealing sound when washer went into the "spin" mode. Tub did not spin

Replaced the 2 belts according to instructions received with the belts. Very easy repair

Parts Used:

-

Edward from Stroudsburg, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

28 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lid closes, switch wouldn't turn on machine.

Used toothpick for a year to push switch acctuator far enough to engage switch. Broke my foot and found time to order part thru PartSelect. Went from cast to boot and received part 2 days after ordered. Had difficulty with foot and getting to switch. Went back into PartSelect and figured out how to dis-assemmble panels thru the diagrams. Time on my job doesn't, just that their service and expertise that is available to everyone is there to use. Broken bones or not, I will always get my parts and advice from PartSelect. Thanks to PartSelect.

Parts Used:

-

Kenneth from Wilmington, IL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

30 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking siphon break valve

1. Unplug power to the washer.

2. Remove 2 screws from bottom front panel on either side. Panel then rotates out and unhooks at the top. Remove front panel

3. Remove bolts from underneath the top front on both sides using a socket.

4. Rotate the top upward to provide space to see and work.

5. From the back of the washer, remove 4 bolts using a socket around the drain tube at the upper left.

6. From the front, the siphon valve can be removed from the inside upper right.

7. From the front, unscrew the clamp holding the drain hose on the water pump housing at the bottom right front and remove the hose. Be prepared for water to drain from the hose. Remove hose and siphon valve together and discard.

8. Install new hose on new siphon valve and screw new clamp tight. Make sure the rubber ring is inserted properly on the new valve (See old valve for reference)

9. Holding the siphon valve in place, use a socket and re-attach the 4 bolts around the drain tube at the back of the washer.

10. From the front, insert the opposite end of the new hose to the water pump at the lower right front and screw the circle clamp tight. Note: Re-use existing clamp.

11. Rotate the top back down into normal position.

12. Plug the power back in and run a short cycle and watch for leaks.

13. If no leaks, re-attach bolts for the top with a socket.

14. Re-attach front panel with 2 screws. Done.

2. Remove 2 screws from bottom front panel on either side. Panel then rotates out and unhooks at the top. Remove front panel

3. Remove bolts from underneath the top front on both sides using a socket.

4. Rotate the top upward to provide space to see and work.

5. From the back of the washer, remove 4 bolts using a socket around the drain tube at the upper left.

6. From the front, the siphon valve can be removed from the inside upper right.

7. From the front, unscrew the clamp holding the drain hose on the water pump housing at the bottom right front and remove the hose. Be prepared for water to drain from the hose. Remove hose and siphon valve together and discard.

8. Install new hose on new siphon valve and screw new clamp tight. Make sure the rubber ring is inserted properly on the new valve (See old valve for reference)

9. Holding the siphon valve in place, use a socket and re-attach the 4 bolts around the drain tube at the back of the washer.

10. From the front, insert the opposite end of the new hose to the water pump at the lower right front and screw the circle clamp tight. Note: Re-use existing clamp.

11. Rotate the top back down into normal position.

12. Plug the power back in and run a short cycle and watch for leaks.

13. If no leaks, re-attach bolts for the top with a socket.

14. Re-attach front panel with 2 screws. Done.

Parts Used:

-

Steven from Indianapolis, IN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

24 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer wouldn't let the water spin out!

I was told that it might be a clog in the tube.. we check the tubes that wasn't it Then I Google it and was told it might be the drain pump. I was just glad that Part Select had what I need because my machine is over 20 years old. We change the pump and now I hope I get at least another 20 years out of my machine. I will always use part select to get my parts. Thanks

Parts Used:

-

SHARON from DETROIT, MI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

22 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leaking from bottom of machine

I had trouble initially because I could see that the inside of the machine was wet but could not get it to leak while I was watching. Finally while the machine was filling I put my hand over the fill opening in the tub and then I got plenty of water coming from the air gap in the injector hose. When I dismantled the injector hose and air gap, I could see that the rubber injector vale was bad. I orgered both a rubber injector and injector hose with air gap. I did this because I couldn't determine if the assembly came with the injector valve. It did so I returned the injector valve.

A word of caution. When I started filling the machine water gushed out the air gap. With a little experimenting with the air gap and injector valve, I determined the rubber injector valve was in backward. After reversing the vale, everything worked fine. This was a sealed package so I would have to say this came from the manufacturer wrong.

A word of caution. When I started filling the machine water gushed out the air gap. With a little experimenting with the air gap and injector valve, I determined the rubber injector valve was in backward. After reversing the vale, everything worked fine. This was a sealed package so I would have to say this came from the manufacturer wrong.

Parts Used:

-

GARY from ILLIOPOLIS, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

21 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor Froze

Make sure to release the springs and pulleys before you try to tackle the bolts that hold the motor base to the bottom of the washer. Mine were a bit rusty and took some force to break loose. Also it's a good idea to take pictures of how everything sits before you disassemble as the pictures in the repair kit are not very clear. Other than that it was pretty straight forward. Wiring was a breeze. . . . Good luck

Parts Used:

-

Matt from Oxford, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

22 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaked from top, left corner of machine.

Removed front of machine; then tilted back the top of machine, after removing the two screws in top front. Removed the old parts, trimmed the injector hose which was slightly longer than necessary, put new injector nozzle in ruber injector valve and inserted into the new sleeve, clamping the new hose to sleeve as well as clamping the remaining functioning hose to sleeve. The new sleeve mounting bracket was slightly different from the old one, but I was able to make it work with a small block of wood and two screws. The washing macine no longer leaks, the parts arrived timely, and the price was right. Thanks.

Parts Used:

-

Robert from Hudson, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

21 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would fill up, wash, then stop

I deduced the lid switch was the problem.

I removed the two screws holding the control panel on. Pulled the control panel back.

Disconnected the ground wire of the lid switch.

removed the two top clamps that hold the panel to the top of the machine.

Pulled back the casing (outside of the washer) and placed it on it's side on the floor. Here I could reach the switch. Removed old, installed new and reversed the process.

The part that gave me the biggest problem was setting the casing back on to the frame. You have to slide the front part in at the bottome, then lean back the rest of it.

I removed the two screws holding the control panel on. Pulled the control panel back.

Disconnected the ground wire of the lid switch.

removed the two top clamps that hold the panel to the top of the machine.

Pulled back the casing (outside of the washer) and placed it on it's side on the floor. Here I could reach the switch. Removed old, installed new and reversed the process.

The part that gave me the biggest problem was setting the casing back on to the frame. You have to slide the front part in at the bottome, then lean back the rest of it.

Parts Used:

-

Glen from Plano, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

22 of 30 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator Not Woking

Unplugged power cord then disconnected the water supply and drain hose. Removed 2 screws and took the front panel off. Laid washer on it's side and posistioned the transmission with the cover facing upward. Removed the hex head screws then used a razor knife and a putty knife to remove the silicone sealant. Found that the agitator shaft spring had broken and fallen into the housing jamming the gears that's used in agitation. Removed the oil and all broken pieces of the spring. Installed new shaft spring, replaced the oil then applied sealant to the cover and screwed the cover back down. Let the washer stay in the same posistion for about 18 hours to let sealant dry completely. Then I sat the washer back on it's feet and removed 2 screws that holds the top lid in place. This allowed me access to the tub cover where the injector t is located. Installed the injector t along with the injector tube seal. Connected the hose and hose clamp. Then I put the lid back down and secured with the screws. Connected the water supply and drain hose then the power and selected a wash time and observed the operation. Everything worked ok so I put the front cover back on. Note: I had used the injector t from this washer to fix another washer that an appliance dealer had given me to use for parts to repair the one just described above. That was the only thing that was wrong with it. It was used for about a year and a half and it developed a problem in the spin cycle. Appears to be a brake problem. I intend to repair it as well.

Parts Used:

-

Richard from Alexander City, AL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

injector hose leak

You can read elsewhere about how to open an old Maytag top-load washer. Two screws in the front holding the front on, and two screws underneath the 'ceiling'. That exposes the injector hose assembly.

Disassembly of old parts is a breeze. A challenge is that the new included plastic mount for the injector doesn't match the original. What I call is the mount, partselect.com calls an "injector sleeve bracket". In hindsight, I could have/should have just used the old mount again. My solution was to file a groove on the underside of the new mount, and use that as a guide for a wire tie that wraps around the mount and the L-bracket coming off of the side of the washer. I suspect that vibration and age will do in the wire tie in a couple of years. I plan to replace it with a hose clamp before that happens.

My understanding is that they really don't make washers like this anymore - the A512 - so I'm very happy to fork over a few dollars in order to keep this one running. We're in our 25th year of operating this one. Every additional year is a bonus!

Disassembly of old parts is a breeze. A challenge is that the new included plastic mount for the injector doesn't match the original. What I call is the mount, partselect.com calls an "injector sleeve bracket". In hindsight, I could have/should have just used the old mount again. My solution was to file a groove on the underside of the new mount, and use that as a guide for a wire tie that wraps around the mount and the L-bracket coming off of the side of the washer. I suspect that vibration and age will do in the wire tie in a couple of years. I plan to replace it with a hose clamp before that happens.

My understanding is that they really don't make washers like this anymore - the A512 - so I'm very happy to fork over a few dollars in order to keep this one running. We're in our 25th year of operating this one. Every additional year is a bonus!

Parts Used:

-

Theodore from Millbrae, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

18 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer wouldn't spin or drain

removed face of washer and replaced belts. The only problem I had was didn't own any torx security drivers.

Parts Used:

-

George from Madison, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

23 of 34 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stripped leveler screw making impossible to level my washer

Put blocks under the washer where the leveling leg was needed and screwed the part into the washer. Then it was just a matter of moving the washer into place and leveling. Pretty easy.

Parts Used:

-

Rebecca from Wylie, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench set

21 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaking badly and making loud noise on spin

Determined the tub seal was bad and ordered the seal and tub bearing. Removed the front cover with two phillips screws and unbolted the top to lift back. Removed the agitator with 1/4" setscrew on side and lifted out. Using punch and hammer, broke the inner tub nut loose (clockwise is off). Lifted out the inner tub, unscrewed springs from the bottom and removed; then removed the bearing with a little prying (had to raise the tub slightly and tap the center splined shaft to push out) and lifted out the outer tub. Outer tub had few rust spots about to penetrate, so sanded off rust, primed with etching auto primer and sprayed enamel topcoat to prevent further corrosion. Reassembled in the same order.

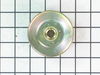

When done, there was still a loud noise on the spin cycle, so obtained a spin bearing and brake assembly (need to replace both most always). Tilted the machine on its back and removed the pulley, then put a special wrench on the brake assembly and broke loose (counterclockwise) with a 3 foot extension after placing a 2x4 section in the tub between wall and one of the bases for the spring arms (to keep the tub from turning). When the brake came off it was full of water and corroded from the leaking tub bearing previously replaced. Reassembled in reverse order and replaced two belts on the bottom for good measure. Works perfectly now and is very quiet.

In my estimation, the repair should have included both the tub bearing/seal and the spin bearing/brake assy from the outset. Could have used a chain visegrip wrench instead of special tool to remove the brake assy - whatever is available. The tool costs a lot and will never be used again.

When done, there was still a loud noise on the spin cycle, so obtained a spin bearing and brake assembly (need to replace both most always). Tilted the machine on its back and removed the pulley, then put a special wrench on the brake assembly and broke loose (counterclockwise) with a 3 foot extension after placing a 2x4 section in the tub between wall and one of the bases for the spring arms (to keep the tub from turning). When the brake came off it was full of water and corroded from the leaking tub bearing previously replaced. Reassembled in reverse order and replaced two belts on the bottom for good measure. Works perfectly now and is very quiet.

In my estimation, the repair should have included both the tub bearing/seal and the spin bearing/brake assy from the outset. Could have used a chain visegrip wrench instead of special tool to remove the brake assy - whatever is available. The tool costs a lot and will never be used again.

Parts Used:

-

Barry from Brooklyn, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no water drain

removed old pully, put new one on with hex driver, removed belts, put new belts on and finished.

Parts Used:

-

Franz from Lakeland, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!