A100 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

missing drip bowls

Our stove is from 1978 and was missing all but one drip bowl. I bought all the replacement parts from all the store, (Walmart, Target, Fred Meyer) nothing fit. I finally found this site and they fit perfectly! Thank you. If I have to keep the stove a while longer at least it looks clean and new now, and it still works great!

Parts Used:

-

Erin from Coeur D Alene, ID

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

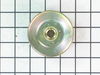

The washing machine ran noisily

Remove the power cord and water hoses. Lay the machine on the floor. Remove two belts (washing and pumping). Unlock the screw of pulley using a hex key. Remove the broken pulley from the motor. Place in the new pulley. Lock the screw of the pulley. Install two belts. Turn the machine vertically. Plug in water hoses and power cord. Level the machine.

Parts Used:

-

Xuanbao from Norwalk, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine was making a weird churning sound during the wash cycle and was slowly leaking water from bottom.

I followed the instructions on this website to a T. You can take the front cover off and you will notice a small drip from the tub area where the Hub bearings (above the tranny) meets the washing tub. Once you've identified that the leak is indeed coming from that area and not a loose tube. Allow the washer to complete the job and drain the water. Then simply unplug washing machine before starting the process of the repair. It is very important to remember that you must have a spanner wrench before attempting to perform this repair. keywords=spanner+wrench came within two days with Prime Shipping. Also be sure to order the replacement parts from this site. It takes about 3 days to arrive however so be prepared to be without a washer for a few days. Other than that just follow the instructions provided and there is a very good step-by-step video on this site .

Parts Used:

-

Jimmy from FREEPORT, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was not agitating. Thought it was stretched/worn belt. It was not! Transmission is shot!

Could not repair. The gearbox on the agitator was broken and that kept the agitator from working. Do not assume it is a belt problem on a washer built in 1987.

Parts Used:

-

Norman from LAKE ZURICH, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old belts slipping squealing, rubber shavings on floor.

Pull washer out from wall. Remove front panel (2 Philips head screws), swing bottom of panel out, remove panel. Tilt washer backwards, lean against wall to expose area under washer. Roll off old belts, roll on new belts. Move washer back upright, replace front panel, replace the philips screws, move washer back to original position.

Parts Used:

-

Elzo from KALAMAZOO, MI

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

surface color was scratched

remove cartridge unit from cooktop, remove 7 small bolts and 2 screws and remove cover. install new cover and replace hardware that was removed and install back in to the cooktop.

Parts Used:

-

Peter from NAPA, CA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Very old washer was leaking oil and grease drops into the wash water.

Followed the procedures recommended for replacement of all the parts included in the Tub Bearing Kit and the Mounting Stem/Tub Seal kit as illustrated in a detailed, 32 minute repair video for the Maytag A606 washer which is available on YouTube. Many difficulties were experienced in the disassembly procedures due to extensive corrosion of tub bearing and tub stem parts (the washer is 47 years old).

I was not successful in using a special tub wrench that was purchased to break loose the old tub mounting stem and its threaded lock nut. The old tub mounting stem, lock nut, and the tub bearing race had to be cut off the threaded support shaft using a saws-all electric tool. Finally, corrosion on the edge of the tub caused problems with water leaks once the tub top and its rubber tub seal ring were reinstalled and the washer was put back into operation. The bottom line is that it may be questionable to attempt major repairs on washers that are 40+ years old and have any extensive corrosion in internal, mechanical parts.

I was not successful in using a special tub wrench that was purchased to break loose the old tub mounting stem and its threaded lock nut. The old tub mounting stem, lock nut, and the tub bearing race had to be cut off the threaded support shaft using a saws-all electric tool. Finally, corrosion on the edge of the tub caused problems with water leaks once the tub top and its rubber tub seal ring were reinstalled and the washer was put back into operation. The bottom line is that it may be questionable to attempt major repairs on washers that are 40+ years old and have any extensive corrosion in internal, mechanical parts.

Parts Used:

-

William A from PITTSBURGH, PA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No tub spin, burning smell.

Partselect.com gave me a very helpful list of parts per symptom. Said that there is an 88% chance that belts were my problem. Since the machine is 200 miles away I ordered two other parts as well. Belts fixed it! Took front cover off (not totally necessary). When the machine is tilted back belts are exposed underneath. Two belts later I was up and running. This site is really great.

Parts Used:

-

Ginsbach from PHOENIX, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

All water into tub leaked from bottom of machine

To troubleshoot the problem I removed a panel/blank from the back of the machine. I then started to fill the tub while watching the pump. It immediately leaked from the shaft seal. I ordered the part early the next morning. It arrived late the next day. I was able to remove the front panel of the machine by removing a screw at each front corner of the bottom of the machine. The pump was attached with three screws which were simple to remove. The pump was an exact replacement and fit identically to the original. I tensioned the belt, and tested the machine. Before reinstalling the front cover, I cleaned the interior of the machine a bit and replaced a couple of hose clamps whose steel screws had started to corrode. All in all a simple repair.

Parts Used:

-

Steve from Martinsville, IN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

slow leak at bottom of unit.

This job turned out to be alot easier than I thought thanks to the tips I received on the web site. First I removed the agitator with a small nut drive I believe it was 1/4". Than I removed the two screws holding on the lid and lofted it out of the way. This is where the Hammer drill comes in. I had read someone else had used WD40 to help break free the threads and get the retaining ring off the tub it self. I worked on this for about 20 minutes with lube and trying to tap it off with the hammer and tap method. Finally I looked over and sitting there on the self next to the washer was my hammer drill. It can't be any worse than banging on the thing with the hammer. (They proably don't reccomend) but with a straight tip and a couple of quick shots the gaint nut came right off. I will say that my washer being older I could barely even tell where the threads were so I figured why not. It worked great. I then took the tub ring(plastic) at the top off and removed tub. Again a couple of quick shots with the hammer drill and the ring came right off. I did spend a little time making sure everything was clean and then reassembled machine with no more leaks. It may sound strange but it worked great with no fighting the space constraints, the calcium buildup and no damage to machine. If it doesn't work get a bigger hammer. Good luck

Parts Used:

-

alex from ogden, UT

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

motor went out

-

jeff from shepherd, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

14 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner wouldn't heat (wiring failure)

1. Shut the breaker off; Jenn-Air's design will have you working around hot leads if you don't.

2. Raise the control panel

3. Remove burner and unscrew the burner connector; trace the wires back to the control panel bottom and remove them

4. On the replacement connector, add the electrical for the control panel. These are not included and can be found at any hardware store; they are a standard size.

5. Connect the new wires and put everything back together.

6. Reset the break and test.

2. Raise the control panel

3. Remove burner and unscrew the burner connector; trace the wires back to the control panel bottom and remove them

4. On the replacement connector, add the electrical for the control panel. These are not included and can be found at any hardware store; they are a standard size.

5. Connect the new wires and put everything back together.

6. Reset the break and test.

Parts Used:

-

Eugene from San Antonio, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washing machine very noisy took belt off pump and it was normal.

I tipped the washer up on 2by4 blocks used 1/4 inch rachet with 5/16 socket two remove 3 screws and the belt from underneath. Took clamps off hoses yahoo saved l00 bucks!

Parts Used:

-

Russell from Bayside, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leaking out of the bottom of washer

Looked online and found a video for the repair consistent with a water leak. Two screws to remove the front panel of the washer, loosen two hose clamps, remove belt (by hand) and three screws to remove old water pump. Replaced pump, replaced belt (made sure it was tight, but not too tight), replaced water hoses, placed cover back on the front and I was done. Maybe 15 minutes tops. Very, very easy. Works like a charm and saved probably $100 in labor.

Parts Used:

-

Jacob from Coldwater, MI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers, Socket set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would stop spinning on its own

Well I looked on line to see if there were any similialtys to my problem and followed what they had done on their washing machines. I replaced the water pump,the slide control below the motor,and the lid switch.None of these items worked.I called a tech.and he informed me that it sounds like the transmission is bad ,he is coming to my house tonight to take a look at the machine.

Parts Used:

-

Bruce from Stevensville, MD

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!